Project Overview

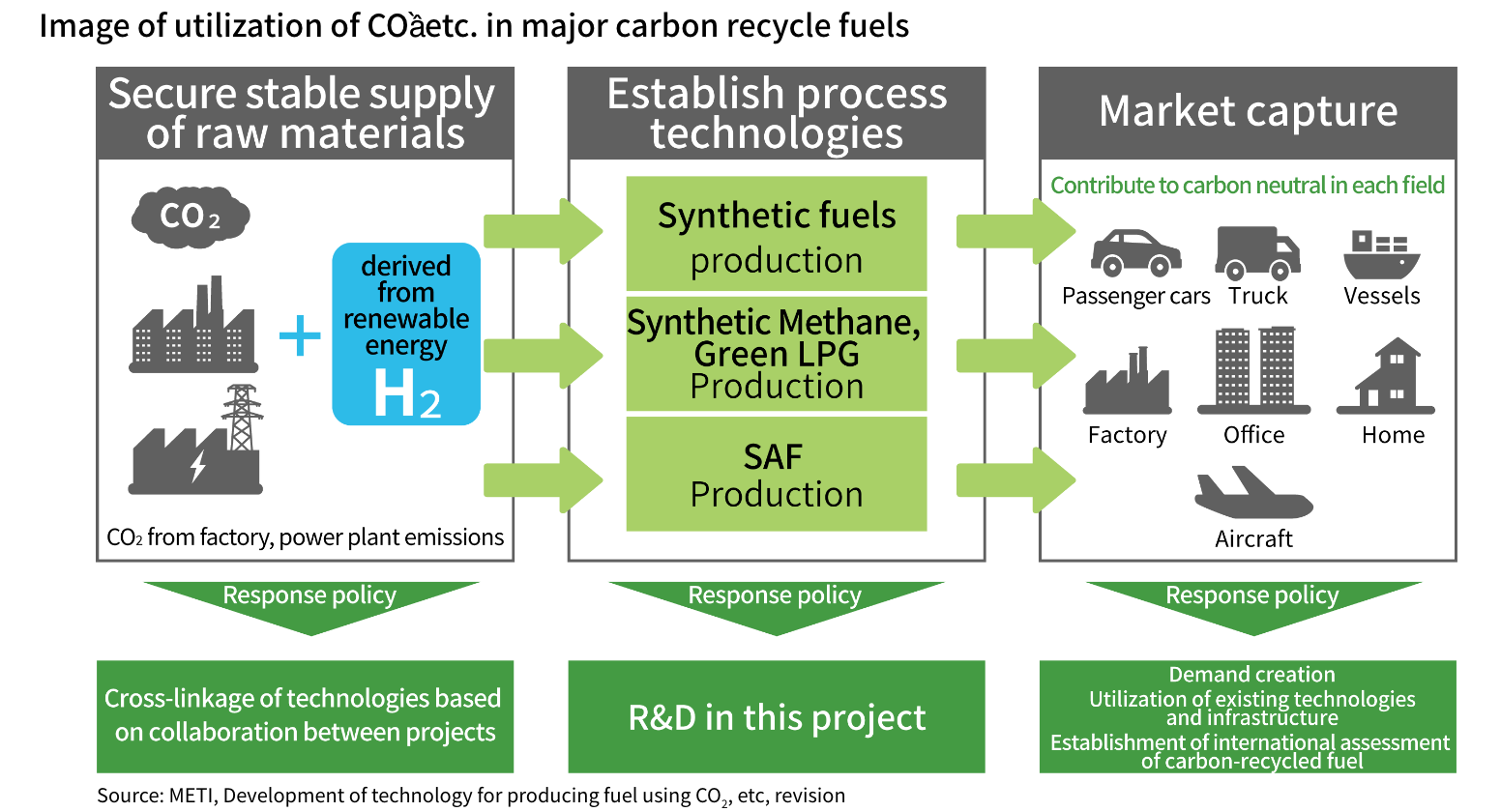

To achieve carbon neutrality by 2050, it is essential to replace fossil fuels with fuels that do not increase CO2 levels in the atmosphere when burned.

Such fuels have the potential to transform the energy supply and demand structure in Japan—which is dependent on fossil fuels from other countries—making it important from the perspective of energy security. Using existing infrastructure will greatly help reduce initial costs. The goal is to solve issues related to production technology and lower production costs to implement them throughout society.

It is necessary to promote the development of technology for carbon recycling fuels as one of the various options for realizing a decarbonized society. This project will work toward the social implementation of two liquid fuels—(1) synthetic fuels and (2) sustainable aviation fuels (SAF)—and two gaseous fuels—(3) synthetic methane and (4) green LPG.

Project Features

〇 Development of technology for improving production yield and utilization technology of synthetic fuels

Develop integrated production process technologies to produce synthetic fuels from CO2 and hydrogen at high efficiency on a large scale and improve the liquid fuel yield rate. Achieve a liquid fuel yield rate of 80% on a pilot scale (planned 300 bbl/day) by 2030 with the goal of making the process independently commercialized by 2040.

〇 Development of technology for producing Sustainable Aviation Fuel (SAF)

Develop Alcohol-to-JET(ATJ) technology to produce SAF from ethanol, which large production volumes (hundreds of thousands of kiloliters) are expected. Achieve a liquid fuel yield rate of 50% or higher and a production cost at the less than 200 yen/L (between 100-199 yen/L) with the aim of supplying the fuel to aircraft by 2030.

〇 Development of innovative technology for the production of synthetic methane

Establish technology for methanation, a process that efficiently synthesizes methane using hydrogen produced from renewables and other energy sources, and CO2 captured at power plants and other facilities. Achieve an energy conversion efficiency rate of 60% or higher by 2030.

〇 Development of technology for synthesizing green LP gas without fossil fuels

Establish technology for synthesizing LP gas (known as green LPG), which is not made from fossil fuels, but synthesized from hydrogen and carbon monoxide using methanol and dimethyl ether. Aim to establish synthesis technology with a production rate of 50% and commercialize it by 2030.