Project Overview

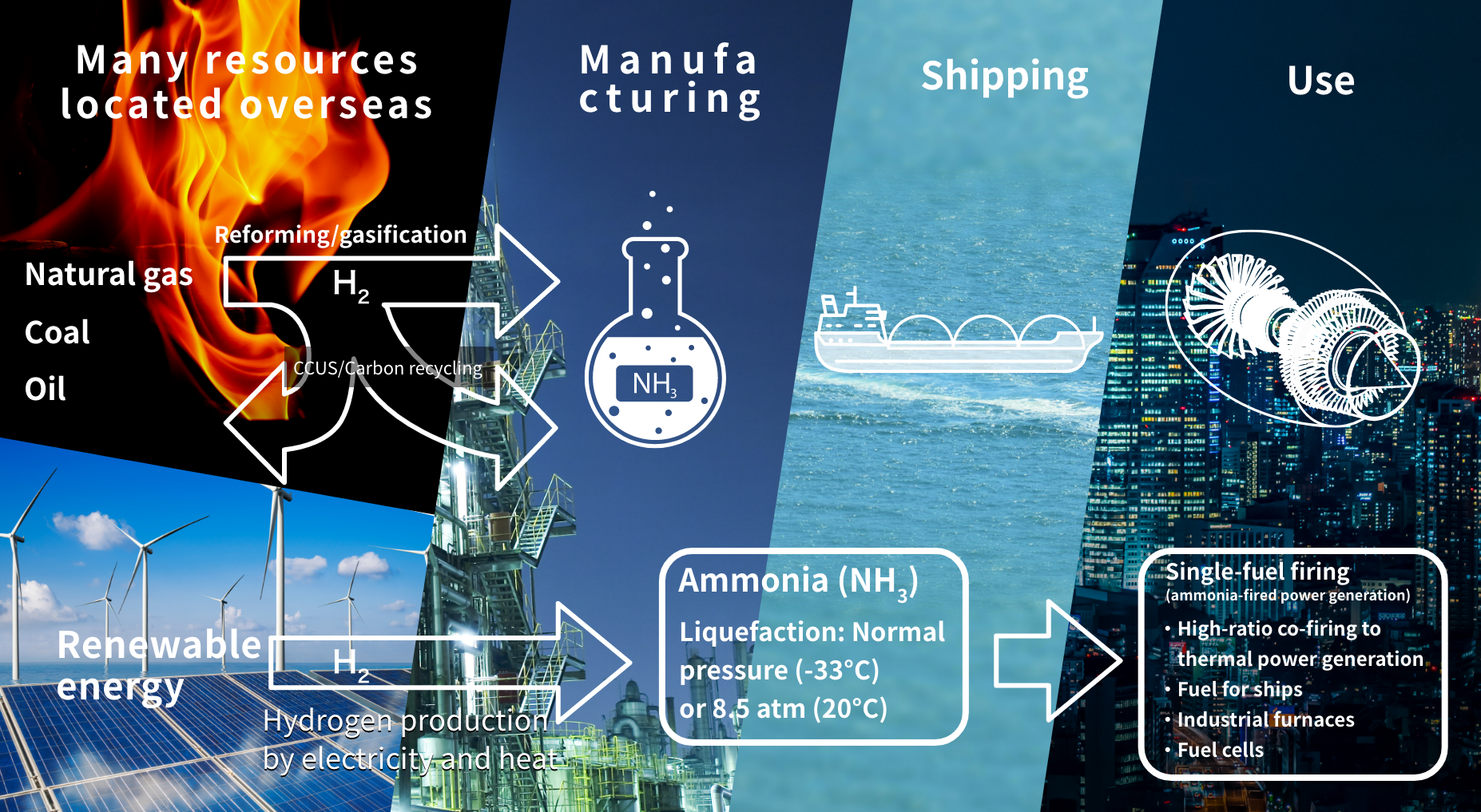

Similar to hydrogen, ammonia does not emit CO2 during firing, so it is expected to be used as a zero-emission fuel for power generation and shipping, thereby helping to realize carbon neutrality. For power generation applications in particular, it is important to promote the decarbonization of thermal power generation by replacing fossil fuels with ammonia. Ammonia can also be used as a hydrogen carrier, so by using existing infrastructure, it can be manufactured and transported inexpensively. Because of these characteristics, ammonia fuel is attracting attention all over the world, and demand is expected to increase rapidly in the future, especially in Asia.

However, ammonia is not currently used as a fuel, so to realize a society where ammonia fuel can be used, various issues must be addressed, such as expanding its use, securing stable supply sources, and reducing its cost.

To address these issues, the aim of this project is to realize technology necessary to reduce ammonia supply costs to the high 10 yen range perNm³ (equivalent to hydrogen bycalorific value) by 2030. Another goal concerns establishing high-ratio co-firing and single-fuel firing technologies for using ammonia power generation to achieve the estimated domestic demand level of 30 million tons/year by 2050.

Project Features

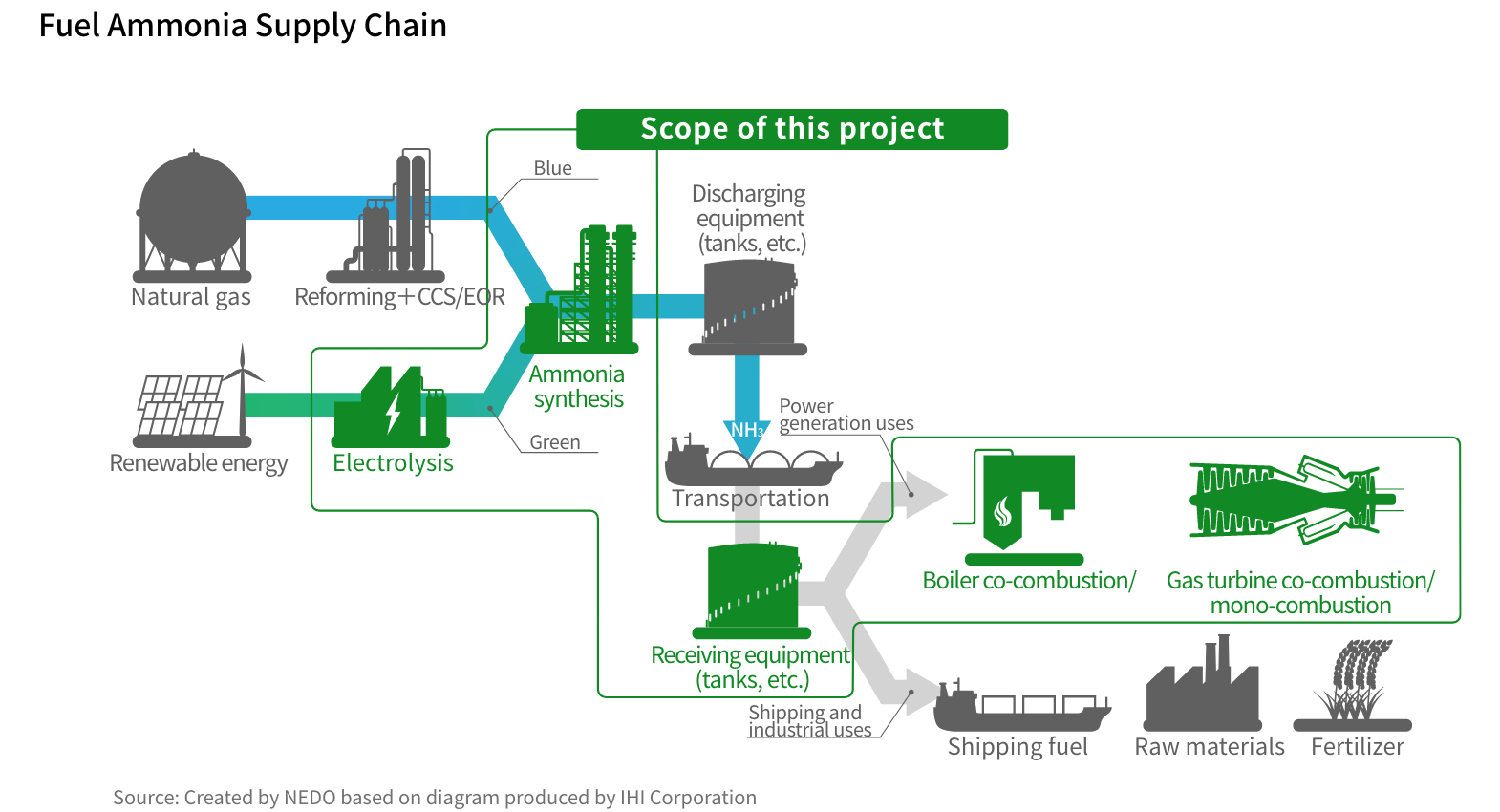

〇 Reduction of ammonia supply costs

The aim of this project is to establish a production system independent of overseas licensors for realizing efficient ammonia production comparable to the existing Haber-Bosch method. Technology will also be developed to produce ammonia directly from renewable energy sources in order to reduce the cost of green ammonia, develop a hydrogen-free manufacturing method.

〇 High-ratio co-firing and single-fuel firing needed for ammonia power generation

Co-firing of ammonia at a level of 20% in coal-fired power generation is progressing, and development of technologies will be pursued for high-ratio co-firing and single-fuel firing of ammonia. Assuming there is demand for replacing coal-fired power plants, technology necessary for single-fuel firing of ammonia in gas turbines will also be developed.