Project Summary

Budget

Up to 39.34 billion yen

CO2 Reduction Effect (World)

- In 2030

- Approximately 330,000 tons/year

- In 2050

- Approximately 560 million tons/year

Economic Effect (World)

- In 2030

- Approximately 0.17 trillion yen

- In 2050

- Approximately 6.8 trillion yen

Research and Development Targets

By 2030, develop hydrogen-fueled engines, fuel tanks, and fuel supply systems and complete the demonstration operation of hydrogen-fueled ships.  Achieve the commercial operation of ammonia-fueled ships as early as possible by 2028 through both the development of ammonia-fueled engines, fuel tanks and fuel supply systems and the establishment of marine ammonia fuel supply systems.

Achieve the commercial operation of ammonia-fueled ships as early as possible by 2028 through both the development of ammonia-fueled engines, fuel tanks and fuel supply systems and the establishment of marine ammonia fuel supply systems.  By 2026, achieve reductions in methane slip of at least 60% on LNG-fueled ships.

By 2026, achieve reductions in methane slip of at least 60% on LNG-fueled ships.

Assumptions regarding estimates of CO2 reduction effect and economic effect

- By 2030, 10 zero-emission ships are expected to be in operation.

- CO2 emissions are expected to total 33,000 tons/year per vessel.

- Reductions of GHG emissions in international shipping through the use of next-generation fuels are viewed as key to realizing the 2050 target adopted by the International Maritime Organization (IMO).

- Price per ship is estimated at 7 billion yen.

- Price per bunker ship is estimated at 5 billion yen.

- The estimated economic impact of shipbuilding has been calculated using an input-output model and is approximately 2.2 times the price for ships.

- The estimated size of the domestic market in 2030 has been calculated on the assumption that shipbuilding volume and prices will increase between 2014 and 2030, while the estimated size of the domestic market in 2050 has been calculated by multiplying the figure for 2030 by the projected rate of growth between 2030-2050. The rate of growth used here is based on the OECD’s long-term forecast for GDP growth.

Research and Development Targets

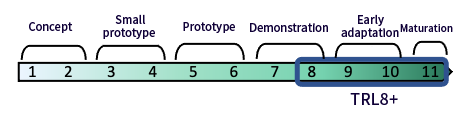

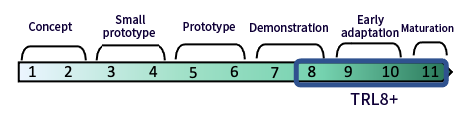

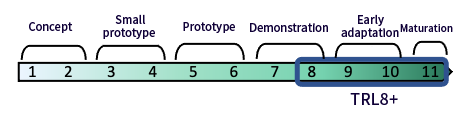

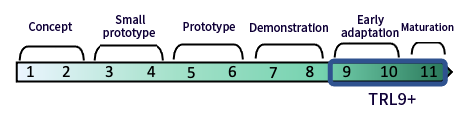

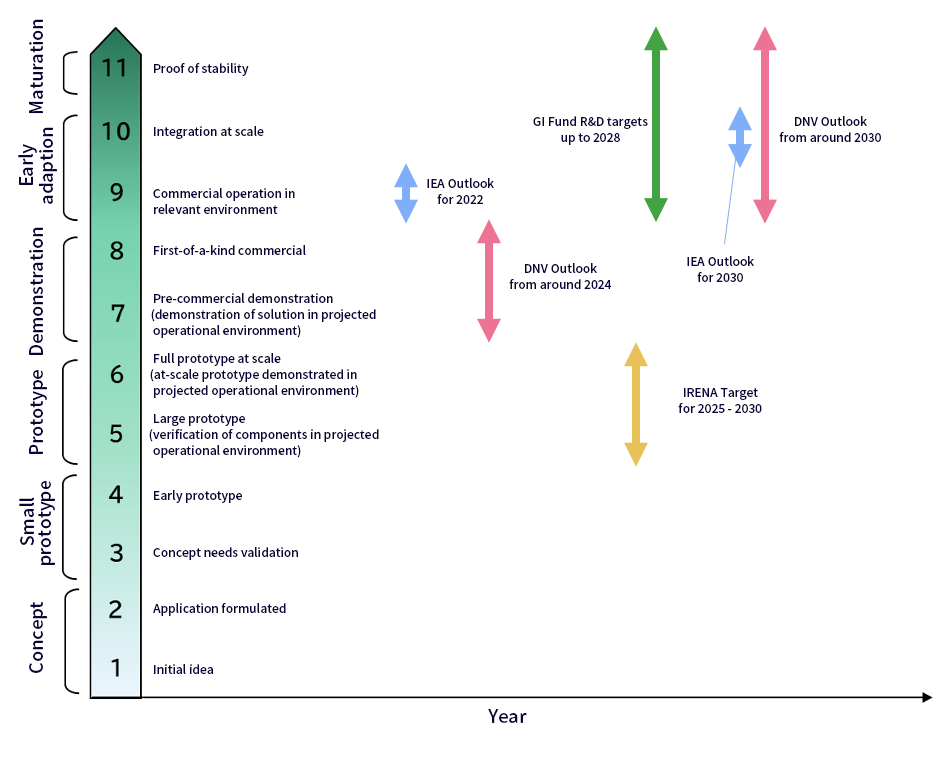

Comparison of Hydrogen-fueled Engine Research and Development Targets

Description of technology readiness levels (TRLs) used by international organizations and classification societies

- IRENA: Implementation period for designing new ships and engines necessary for realizing decarbonization in the shipping sector. (Taken from IRENA report, “A Pathway to Decarbonize the Shipping Sector by 2050,” published October 2021.)

- IEA: Prospects for use on ocean-going ships and major developments. (Taken from IEA report, “Energy Technology Perspectives 2020,” published September 2020.)

- DNV: Demonstration testing and prospects for onboard commercial use (Taken from DNV report, “Energy Transition Outlook 2021,” published September 2021.)

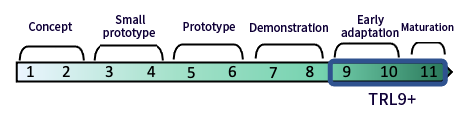

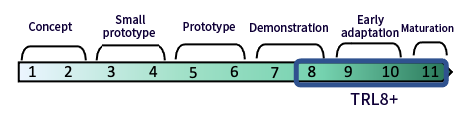

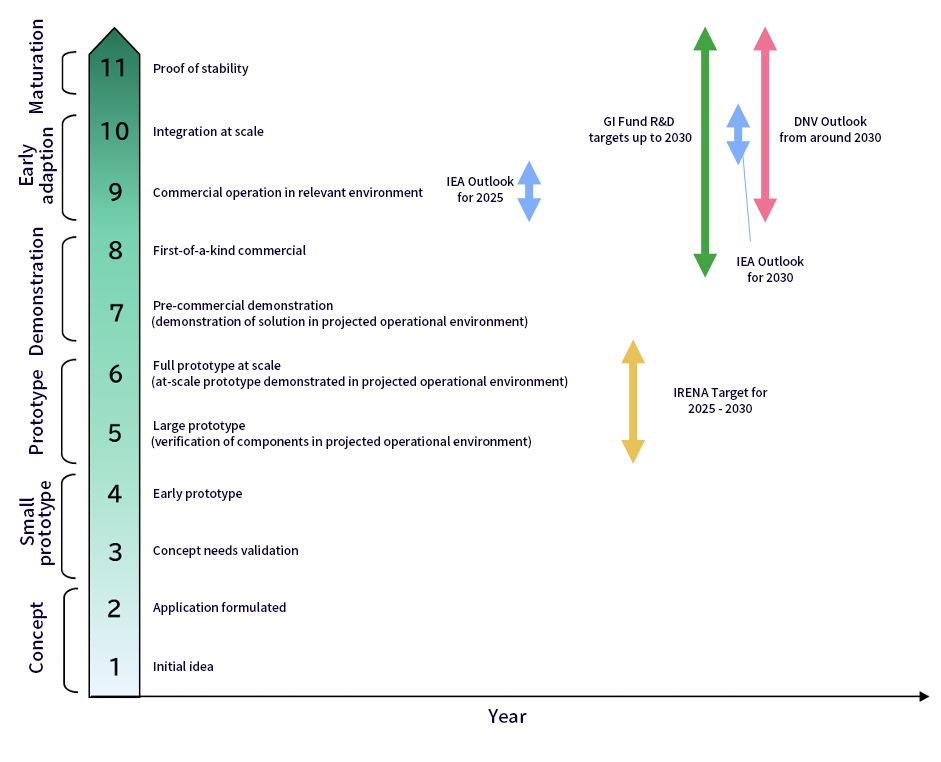

Comparison of research and development targets for ammonia engines

Description of technology readiness levels (TRLs) used by international organizations and classification societies

- IRENA: Implementation period for designing new ships and engines necessary for realizing decarbonization in shipping sector. (Taken from IRENA report, “A Pathway to Decarbonize the Shipping Sector by 2050,” published October 2021.)

- IEA: Prospects for use on ocean-going ships and major developments. (Taken from IEA report, “Energy Technology Perspectives 2020,” published September 2020.)

- DNV: Demonstration testing and prospects for onboard commercial uses. (Taken from DNV report, “Energy Transition Outlook 2021,” published September 2021.)

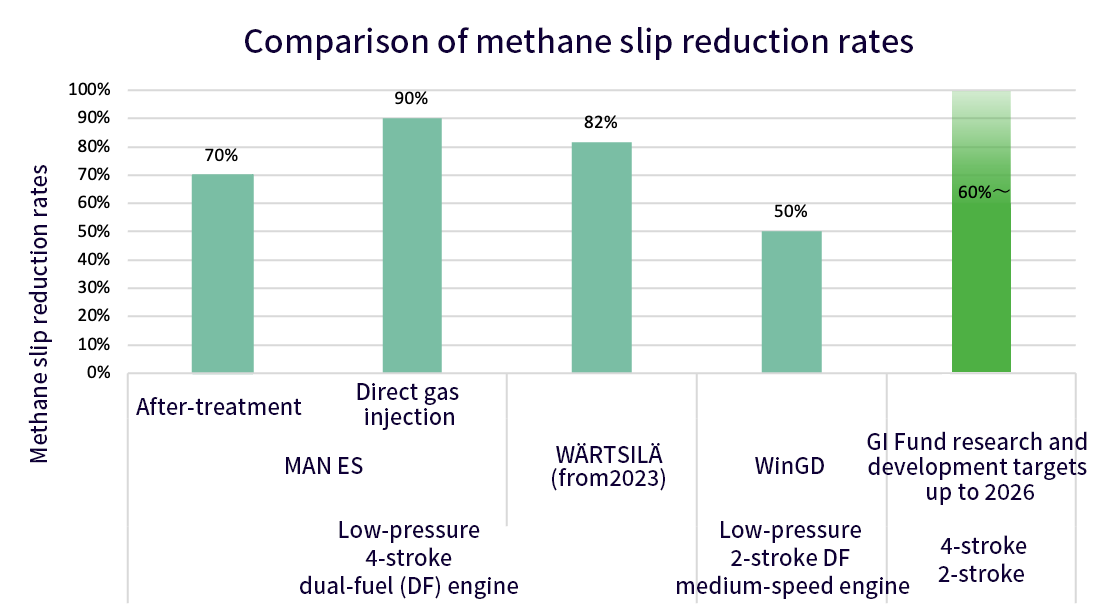

Comparison of methane slip reduction rates

R&D by major manufacturers to address methane slip on LNG-fueled ships

- Man ES: For low-speed DF and medium-speed 4-stroke engines (using IMO standard value of 5.5 g/kWh), methane slip may be reduced 70% by after-treatment of oxidation catalysts and 90% by direct gas injections.

- Wartsila: For low-speed DF and medium-speed 4-stroke engines (using IMO standard value of 5.5 g/kWh), efforts are underway to reduce methane slip by roughly 1.0 g/kWh by 2023.

- Win GD: For low-speed DF and low-speed 2-stroke engines (using IMO standard value of 2.5 g/kWh), methane slip may be reduced by 50%.