Project Summary

Budget

Up to 154.03 billion yen

CO2 Reduction Effect (World)

- In 2030

- 40 million tons/year

- In 2050

- 1.5 billion tons/year

Economic Effect (World)

- In 2030

- 10 trillion yen/year

- In 2050

- 363 trillion yen/year

Research and Development Targets for 2030

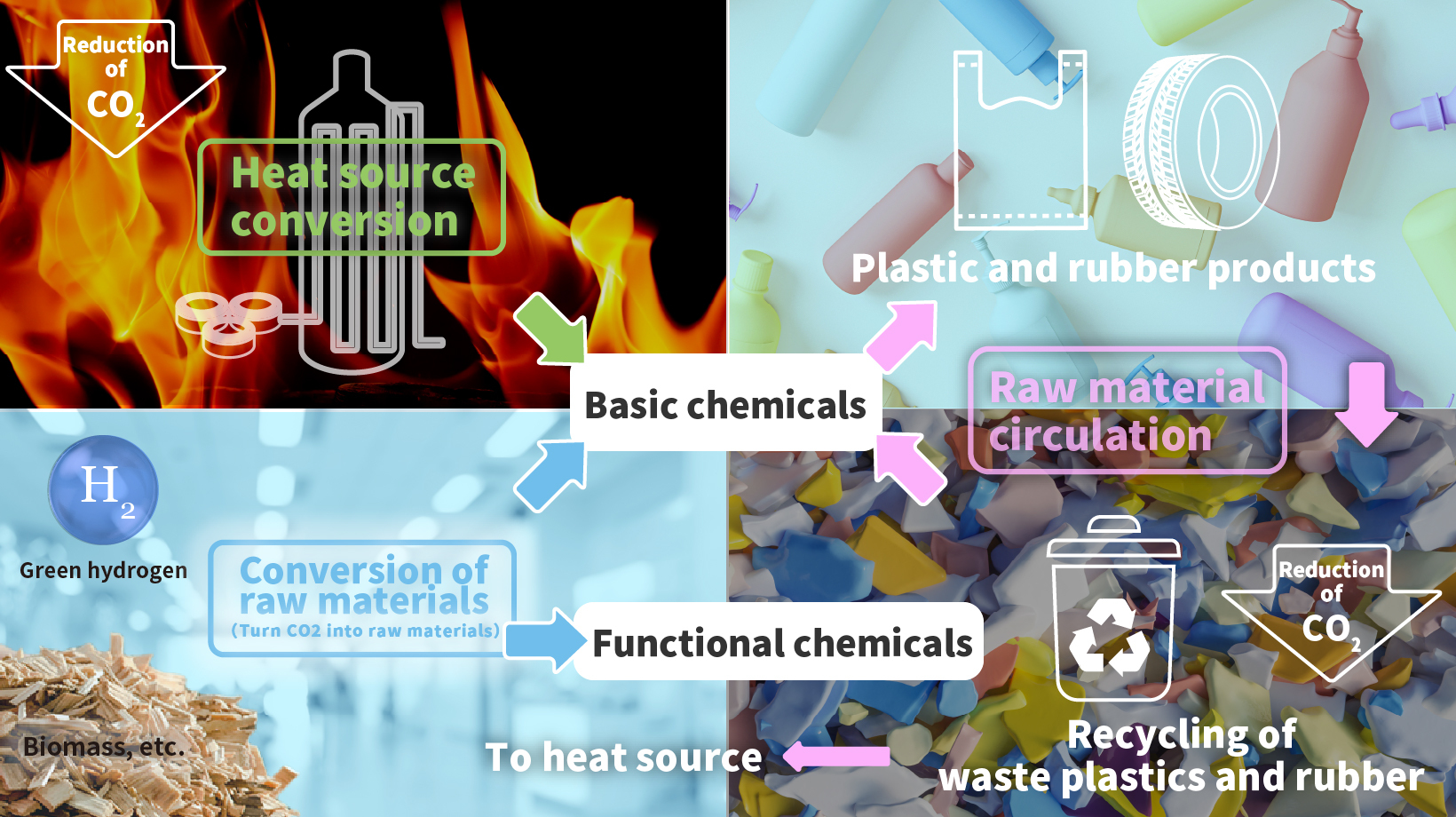

- Development of furnaces and burners that thermally decomposes naphtha using ammonia or hydrogen as heat sources without emitting CO2 and realization of technology to reduce energy consumption and cost to the same level as those produced from the current naphtha cracking furnace.

- Development of chemical recycling technologies of waste plastics and rubbers to reduces CO2 emissions and manufacturing costs significantly.

- Reduce CO2 emissions by developing technologies to manufacture polycarbonate and polyurethane from CO2 and improve functionality.

- Develop technologies for producing chemicals from CO2-derived alcohols with the following levels of efficiency and durability:

- Develop photocatalysts having solar-to-hydrogen conversion efficiency of 10% or more, and demonstrate the probability of achieving hydrogen production costs to less than 30 yen/Nm3.

- Accomplish the technology that produce basic chemicals such as ethylene and propylene from hydrogen and CO2 via alcohols with production yield 80-90%, catalyst durability of more than 10,000 hours, 20% lower production cost compared with existing CO2-derived methanol to olefin (MTO) process

Assumptions for estimation of CO2 reduction effect

- Estimates calculated on basis of production volumes of olefin, “green” hydrogen, methanol, ethanol, etc. multiplied by amount of CO2 emissions reduction for target date of 2030.

- Estimates calculated by adding amount of CO2 emissions reduction realized through adoption of carbon-free heat sources in naphtha cracking furnaces for target date of 2050.

Assumption for estimates of economic effect

- Estimates for target date of 2030 calculated by assuming demonstration testing will be implemented at one-thirtieth of full scale.

- The market size for plastics in 2050 will be nearly the same as now.

Assumption for estimates of CO2 reduction effect and economic effect

- The impact of global CO2 reduction and the forecast size of global market have been estimated by calculating backwards from Japan’s 2.8% share of current global production capacity of ethylene plants.