Project Overview

To achieve carbon neutrality by 2050, it is essential to introduce renewable energy as much as possible. Given the feasibility of large-scale introduction and cost reductions as well as the anticipated economic ripple effects, offshore wind power generation holds the key to making renewable energy a main source of power.

Offshore wind power has been expanding mainly in Europe, but the Asian market is expected to grow rapidly between now and 2050. Especially in Japan and other parts of Asia, which have large areas of deep sea, there is an increasing need for systems optimized to suit local oceanographic and meteorological conditions, such as low wind speeds, typhoons, and lightning strikes.

The aim of this project, therefore, is to establish technology that can achieve a power generation cost of 8 to 9 yen/kWh with fixed-bottom wind turbines under certain conditions, and technology to commercialize floating offshore wind turbines at internationally competitive cost levels.

Based on the results of demonstration projects carried out thus far, the cost of offshore wind power, particularly for floating wind turbines, can be quickly reduced, thereby facilitating an expansion in public implementation efforts.

Project Features

〇 Technology development project for next-generation wind turbines

In addition to the technological capabilities gained from onshore wind power and domestic manufacturing infrastructure, under this project, the overall value chain for wind turbines will be streamlined and optimized by leveraging Japan's strengths in the areas of manufacturing technologies, quality control, and robotics/factory automation. With a view toward collaboration with global manufacturers, development of wind turbine technologies will be pursued to optimize wind turbine specifications and realize high-quality mass production.

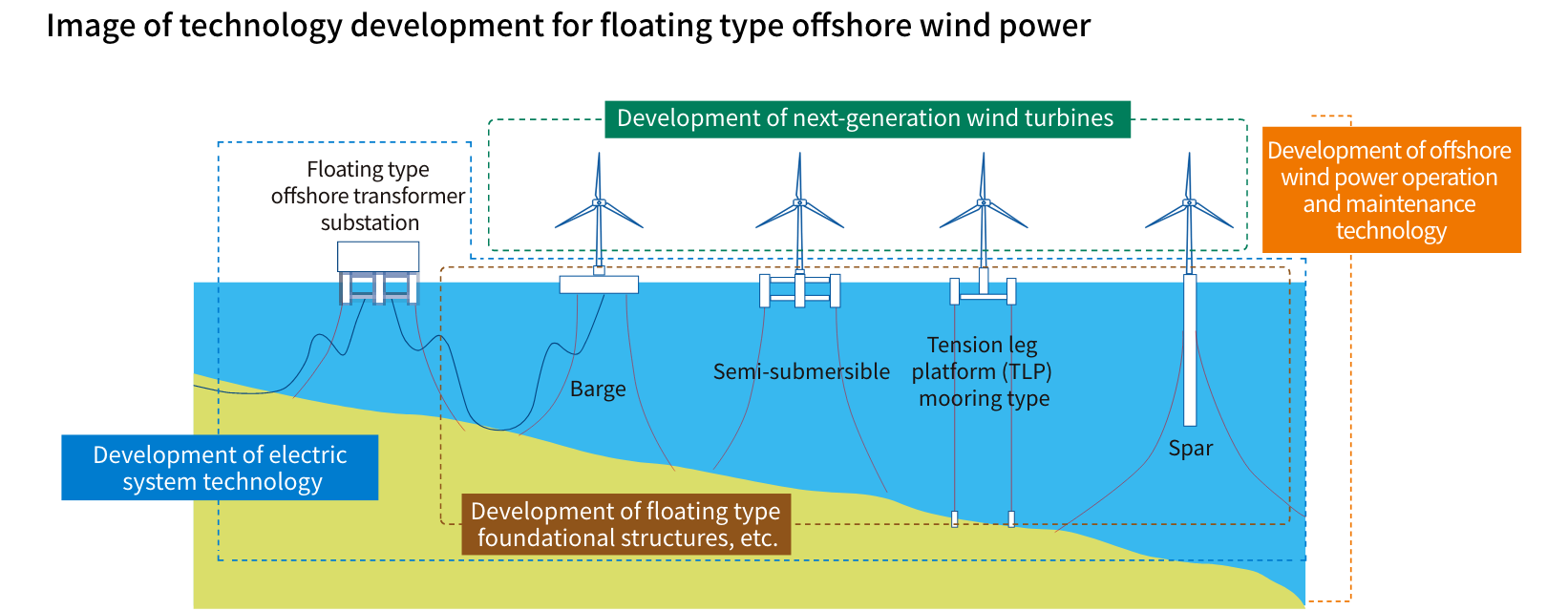

〇 Technology development project for basic manufacturing and installation cost reduction for floating wind turbines

By leveraging Japan's shipbuilding technologies and infrastructure, such as docks, under this project, technologies will be developed to optimize floating bases and mooring systems. Low-cost construction technologies will also be developed to realize the world's first mass production system for floating turbines.

〇 Technology development project for offshore wind power-related electrical systems

By leveraging the technological capabilities of globally competitive domestic cable manufacturers, technology development will be pursued on floating offshore substations and high-voltage dynamic cables optimized to withstand severe meteorological conditions, such as typhoons, and oceanographic conditions, such as sea swells, which frequently occur in Japan and other parts of Asia.

〇 Innovative offshore wind power operation and maintenance project

By leveraging Japan's advanced smart maintenance technologies developed for onshore wind power, technology development will be pursued related to operations and monitoring/inspection activities with a view to enhancing maintenance activities, which account for over 30% of total costs.

〇 Floating offshore wind turbine demonstration project

Since it is necessary to improve reliability and reduce costs through an integrated design that considers the behavior, performance, workability, and cost of components, such as wind turbines, floats, mooring systems, and cables, a comprehensive demonstration of the technologies used for the integrated system will be carried out. Given the goal of reducing power generation costs, end-users, (such as power generation companies) will be involved in the demonstration.