Project Summary

Budget

Upper limit of32.51billion yen

CO2 Reduction Effect

- In 2040

- Approx20million tons/year (Japan)

- In 2050

- Approx80million tons/year (Japan)

Economic Effect

- Total up to 2040

- Approx4.2trillion yen

- Total up to 2050

- Approx10.0trillion yen

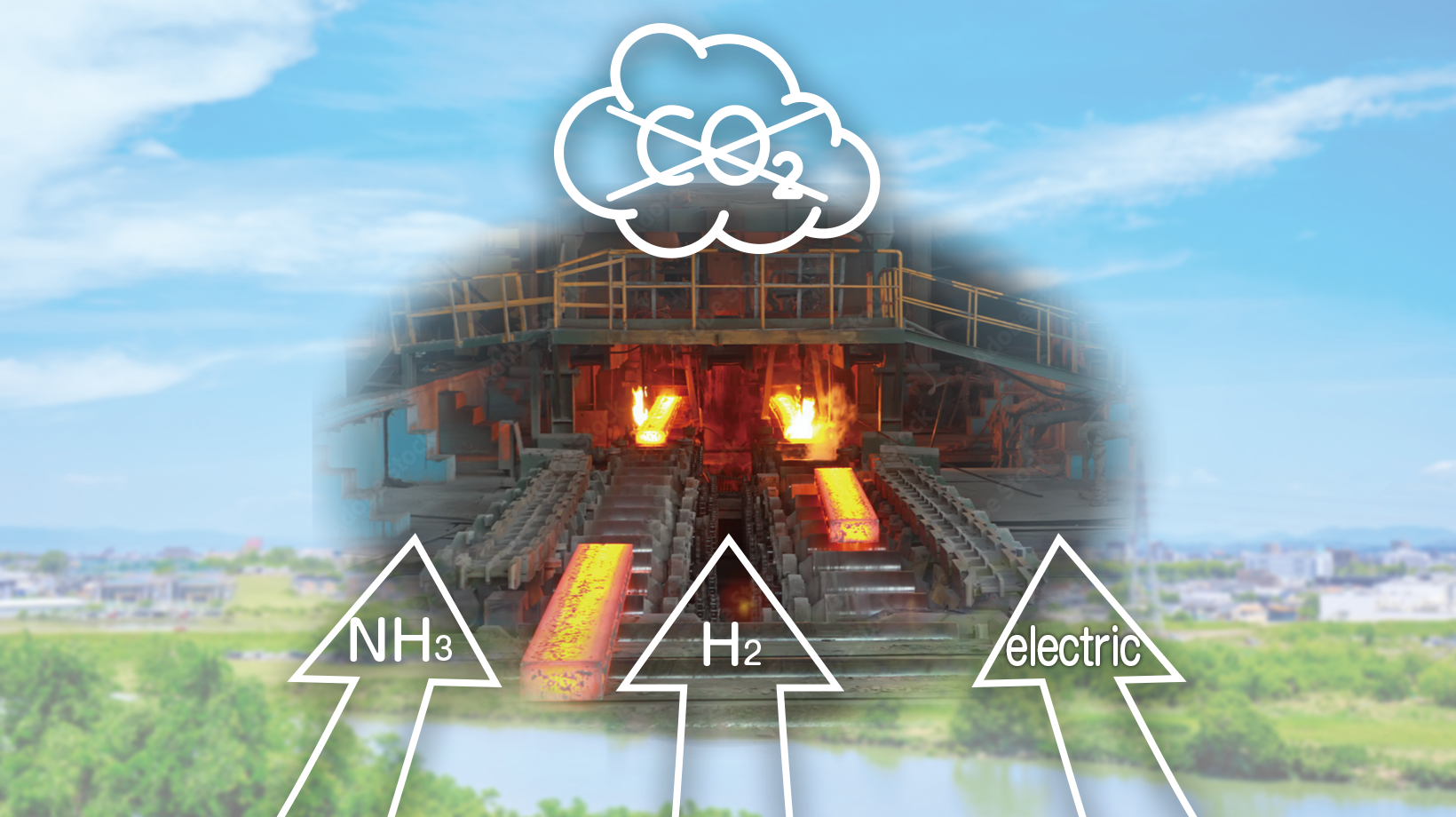

Research and development program targets

(2) Achieve TRL 6 or higher equivalent* for firing technology with 100% mono-fuel combustion technology that achieves the same or higher level of metal product quality, NOx emissions, combustion stability and control, long-term operational stability, etc., compared to existing industrial furnaces by FY2031.

*Equivalent to IEA TRL6 or higher: Demonstration in a system model or prototype equivalent environment.

(2) Achieve TRL 6 or higher equivalence for hydrogen combustion technology with 100% mono-fuel combustion technology that achieves the same or higher level of metal product quality, NOx emissions, combustion stability and control, long-term operational stability, etc., compared to existing industrial furnaces by FY2031.

*Equivalent to IEA TRL6 or higher: Demonstration in a system model or prototype equivalent environment.

(2) Establish energy conservation technologies of 15% or more compared to existing electric furnaces through the establishment of technologies to utilize waste heat from electric furnaces, high-power heaters, and technologies to prevent deterioration and extend the service life of resistive elements by FY2028.

[Assumptions for CO2 reduction effects]

Estimates are based on the assumption that the supply of ammonia and hydrogen, which is a government program target, will progress as planned, without considering the supply constraints of energy sources. Under the assumption that the number of 37,000 industrial furnaces in Japan will not change, we estimate that a certain number of furnaces will be replaced every year with furnaces with 50% ammonia/hydrogen co-combustion with other fuels (or equivalent electric furnaces) after FY2032, based on the amount of CO₂ emissions per base. The calculation assumes that after FY2040, a certain number of furnaces (or equivalent electric furnaces) with 100% ammonia/hydrogen co-combustion with other fuels will be replaced every year.

[Assumptions for economic effects]

It is estimated that the 37,000 industrial furnaces in Japan will be spread (renewed) with a certain number (about 1,300 units) of furnaces with 50% ammonia/hydrogen co-combustion with other fuels every year after FY2032, as an added value of about twice the average price of about 100 million yen (including the cost of fuel supply equipment, etc.). The calculation assumes that a certain number (about 1,300 units) of 100% ammonia/hydrogen mono-fuel combustion technology furnace (or equivalent electric furnaces) will be spread (renewed) every year after FY2040. Speaking about overseas, as in Japan, a furnace (or equivalent electric furnace) with 50% ammonia/hydrogen co-combustion with other fuels is estimated to spread every year at about twice the current export value (about 5.3 billion yen) and the number of units (about 530 units), and a 100% mono-fuel combustion technology furnace (or equivalent electric furnace) is estimated to spread every year at about three times the current export value and the number of units, as an added value of about twice the average price of about 200 million yen (including the cost of fuel supply equipment, etc.).