Project Summary

Budget

Up to 449.9 billion yen

CO2 Reduction Effect

- In 2030

- Approximately 2 million tons/year (Japan)

- In 2050

- Approximately 1.3 billion tons/year (World)

Economic Effect (World)

- In 2030

- Approximately 320 billion yen/year

- In 2050

- Approximately 40 trillion yen/year

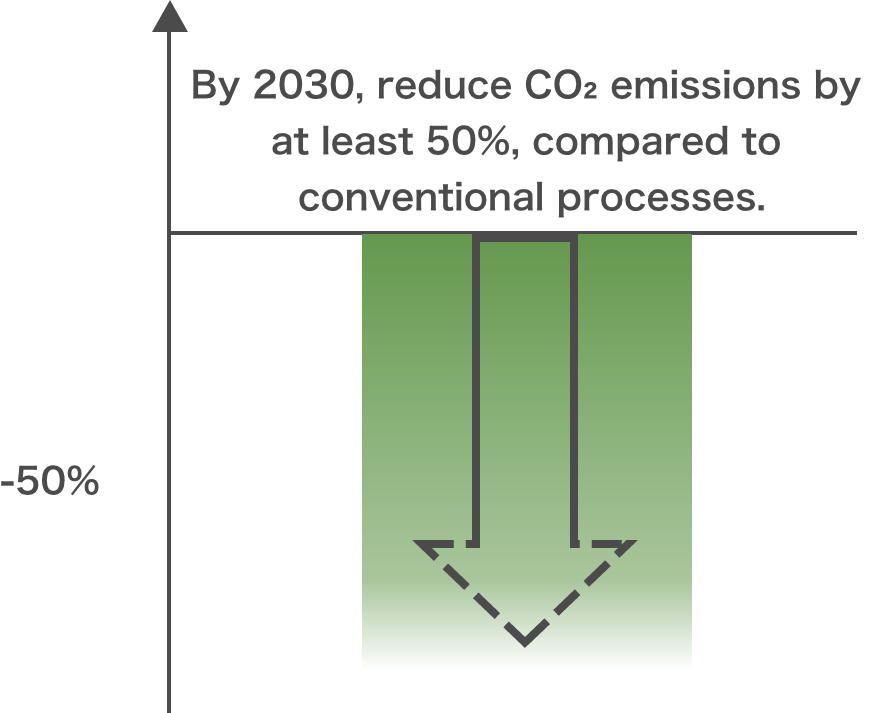

Research and Development Targets

1. Develop hydrogen reduction technology using blast furnaces capable of reducing CO2 emissions by at least 50%, compared to conventional blast furnaces.

2-1. Develop direct hydrogen reduction technology that reduces CO2 emissions by at least 50%, compared to conventional blast furnaces.

2-2. Develop technology capable of controlling impurity concentrations in electric furnaces to levels equivalent to those of blast furnaces.

2-3. Development of technology to control impurity concentrations in electric smelting furnaces at the same level as in the blast furnaces

Assumptions regarding estimates of CO2 reduction effect

- By 2030, COURSE50 (refers to CO₂ Ultimate Reduction System for Cool Earth 50) technology is expected to be utilized in domestic steel plants.

- By 2050, as envisaged in the Iron and Steel Technology Roadmap published in 2020 by the International Energy Agency (IEA), innovative steelmaking technologies, such as those for hydrogen reduction and CCUS, are expected to become widely used around the world.

Assumptions regarding estimates of economic effect

- Estimates calculated on basis of projected 2030 annual output by domestic steel plants utilizing COURSE50 technology.

- Estimates calculated on basis of maximum outputs of “green” steel (i.e. steel produced using hydrogen reduction and CCUS technologies) as described in the IEA’s Energy Technology Perspectives 2020.