Project Overview

Hydrogen can not only directly contribute to the decarbonization of the power generation sector by converting surplus power into hydrogen for storage and utilization, it can also maximize its potential as a zero-emission renewable energy power source. Hydrogen is therefore expected to be used as a secondary energy source for achieving carbon neutrality and contribute to decarbonization in industrial fields such as raw material utilization and heat demand where decarbonization through electrification is difficult.

To promote the social implementation of hydrogen, supply costs must be reduced by increasing the size of supply facilities while also creating large-scale hydrogen demand. However, since long-term hydrogen demand is currently uncertain, it is difficult for private companies to make large-scale investments in infrastructure. To reduce this uncertainty, a social implementation model must be established that can increase supply and create hydrogen demand by maximizing use of existing infrastructure.

In addition to enlarging the transportation facilities, and other resources including hydrogen carriers, the project will implement demonstrations of hydrogen power generation at an actual power plant (co-combustion with other fuels and single-fuel combustion using hydrogen only). The aim is to establish technologies that will make reducing supply costs possible along with creating a large-scale demand for hydrogen, and to achieve a hydrogen supply cost of 30 yen/Nm³ by 2030, and 20 yen/Nm³ or below by 2050 (similar level to fossil fuels).

Project Features

〇 Large-scale hydrogen supply chain demonstration, and development of innovative hydrogen transportation technology

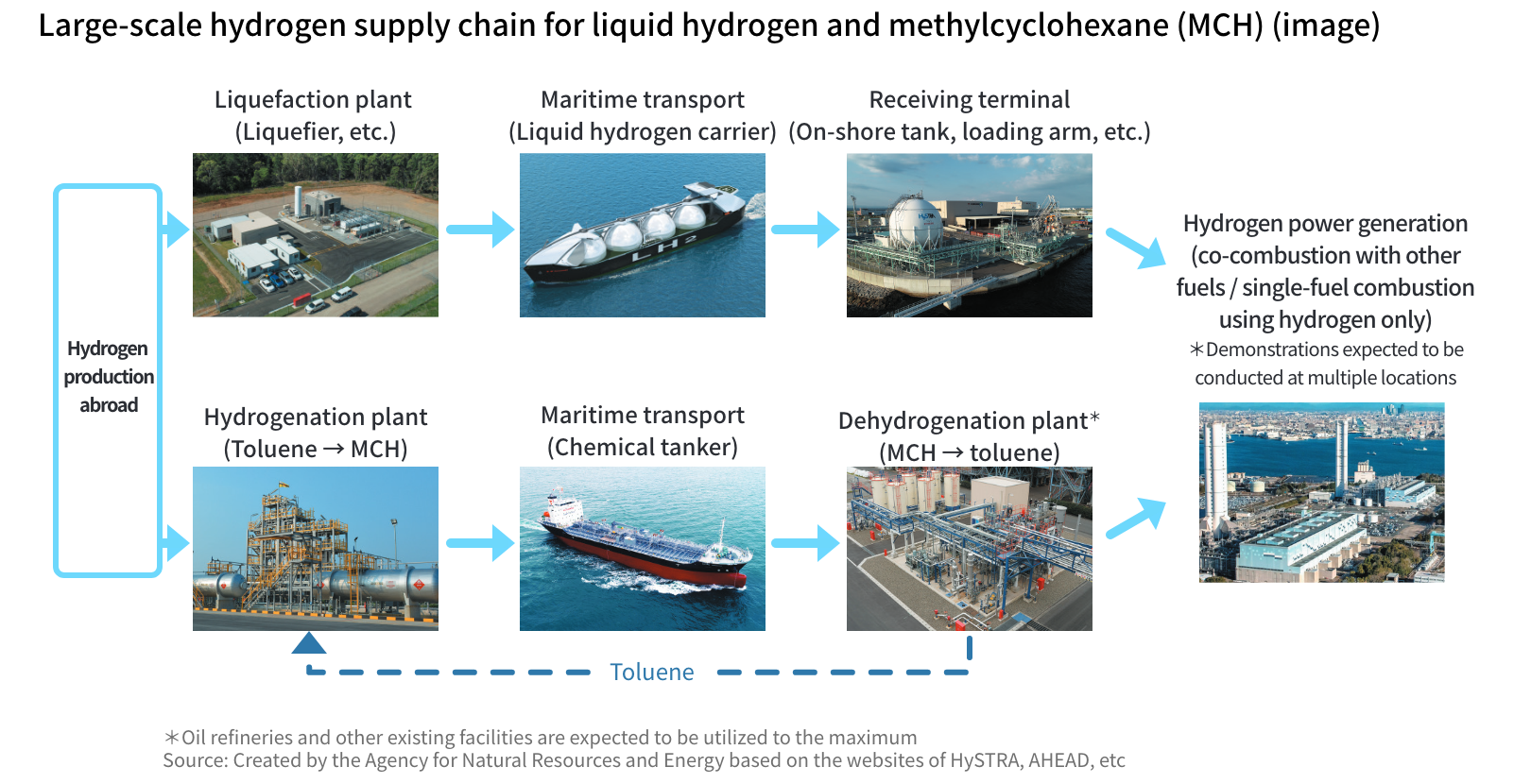

In order to make hydrogen supply costs competitive with fossil fuels (20 yen/Nm³ or below), projects for achieving commercialization of a large-scale hydrogen supply chain are being carried out using liquefied hydrogen and methylcyclohexane (MCH) as a hydrogen carrier. Development of innovative liquefaction and direct MCH electrolytic synthesis technologies is also underway to reduce hydrogen supply costs.

〇 Developing a foundation for material evaluations to support R&D on liquefied hydrogen-related equipment

To help reduce the cost of equipment used in the production, transportation, storage, and utilization of liquefied hydrogen, equipment is being developed that will form the basis for uniformly evaluating the mechanical properties of materials.

〇 Demonstration of hydrogen power generation technology at an actual power plant

To commercialize hydrogen gas turbine power generation technology that will create large-scale demand by 2030, combustors developed through past projects are being used at actual power plants for carrying out various demonstrations to verify combustion stability and address other issues.