In June 2025, a pilot-scale facility for the production of CO2 recycling artificial limestone was completed at the Sumitomo Osaka Cement Tochigi Plant in Sano City, Tochigi Prefecture. This facility will serve as the central hub for “Development of Carbonation Technology Using Various Calcium”, as part of NEDO’s Green Innovation Fund project to ”Development of Technology for Producing Concrete and Cement Using CO2.”

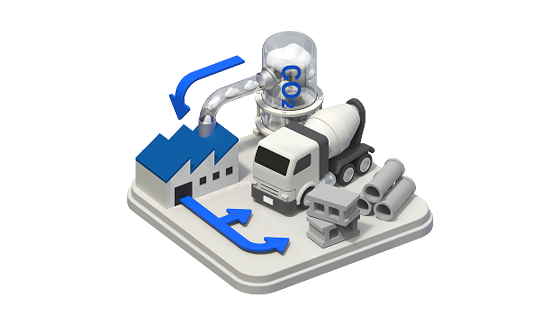

The initiative aims to develop and implement processes that capture CO2 from cement production and combine it with calcium-rich waste—such as municipal incineration ash and waste gypsum board—to produce artificial limestone, a key raw material for cement.

The project’s anticipated outcomes include a significant reduction in CO2 emissions from the concrete and cement sectors, contributing significantly to achieving carbon neutrality. The completion of this new facility represents a major milestone toward that goal.

Top left: Newly completed pilot-scale facility for producing CO2 recycling artificial limestone. Top right: Interior view of the production plant. Bottom left: Reaction between a calcium-rich solution derived from waste materials and a CO2-absorbed solution from flue gas. Bottom right: The gray granule on the left is municipal incineration ash, and the pure white material on the right is CO2 -recycling artificial limestone.

Top left: Newly completed pilot-scale facility for producing CO2 recycling artificial limestone. Top right: Interior view of the production plant. Bottom left: Reaction between a calcium-rich solution derived from waste materials and a CO2-absorbed solution from flue gas. Bottom right: The gray granule on the left is municipal incineration ash, and the pure white material on the right is CO2 -recycling artificial limestone.As the global transition toward decarbonization accelerates, research and development on CCUS (Carbon Capture, Utilization, and Storage) technologies is progressing across a broad spectrum of industries. Among these, initiatives in the concrete and cement sectors are particularly critical, as these industries—together with chemicals and steel—generate substantial CO2 emissions during manufacturing. Cement and concrete production is estimated to account for approximately 7–8% of total industrial CO2 emissions globally.

Building on this context, the ”Development of Technology for Producing Concrete and Cement Using CO2” was launched in FY2021 under NEDO’s Green Innovation Fund Program.

As part of this initiative, Sumitomo Osaka Cement is developing and implementing technologies to produce artificial limestone using CO2 captured during cement manufacturing.

Concrete is produced by combining cement with sand, aggregate, and water. Because CO2 emissions from cement production account for more than 90% of total emissions over concrete’s entire life cycle, the project’s outcomes are expected to make a significant contribution to decarbonization in the concrete and cement sectors.

Turning CO2 Emissions into a Resource

Noriyuki Kozakai, Managing Executive Officer of Sumitomo Osaka Cement and head of the Cement & Concrete Research Laboratory and Sustainability Department

Noriyuki Kozakai, Managing Executive Officer of Sumitomo Osaka Cement and head of the Cement & Concrete Research Laboratory and Sustainability DepartmentLimestone consists primarily of calcium carbonate (CaCO3). During the main process of cement manufacturing, it is heated to temperatures exceeding 1,000°C, initiating a decarbonation reaction that breaks it down into calcium oxide (CaO) and CO2.

This process generates CO2 not only from the fuel used for heating, but also from the decarbonation reaction itself—one of the primary reasons for the industry’s high emissions. Approximately 60% of CO2 emissions in the process originate from decarbonation, with the remaining 40% coming from fuel combustion. Even with more efficient or low-carbon fuels, achieving substantial reductions remains difficult. This underscores the critical importance of CCUS development in cement production.

Noriyuki Kozakai, Managing Executive Officer of Sumitomo Osaka Cement and head of the Cement & Concrete Research Laboratory and Sustainability Department, who oversees the company’s artificial limestone business, stresses the significance of pursuing this business for the company:

"Given that CO2 emissions are inherent to the manufacturing process, it’s clear there’s a limit to how much we can reduce them. That’s why we shifted our thinking to view CO2 as a resource and began R&D to put it to practical use. If resource recovery progresses, we can transform the perception of the company from a 'CO2 emitter' into a company 'with abundant CO2 resources.'"

Since around 2017, the company has been engaged in R&D on CO2 mineralization—producing artificial limestone from CO2 generated during manufacturing processes and from waste materials. When the GI Fund project call opened in 2021, the company moved quickly to apply.

R&D Encompassing Practical Applications

Koji Kawamata, Project Manager and Project Coordinator (Mineralization Section, Circular Economy Department) at NEDO

Koji Kawamata, Project Manager and Project Coordinator (Mineralization Section, Circular Economy Department) at NEDOThe “Development of Carbonation Technology Using Various Calcium” project covers not only the development of technologies for producing artificial limestone, but also the advancement and implementation of its practical applications.

Koji Kawamata, Project Manager and Project Coordinator (Mineralization Section, Circular Economy Department) at NEDO, stresses the project’s distinctive scope:

“Among the many initiatives supported by the Green Innovation Fund, it is rare to find one that spans both foundational technology development and downstream applications.”

The project is specifically focused on developing carbon recycling cement using artificial limestone made from captured CO2. This includes technologies for producing cement using CO2 recycling artificial limestone, as well as applying it in various ways—such as a minor additional constituent, a concrete admixture in concrete, or a key ingredient in limestone-blended cement.

One notable example of the technology in action is the use of carbon recycling cement in the structural components around the Sumitomo Pavilion at Expo 2025 Osaka, Kansai, which is taking place from April 13 to October 13, 2025.

Alongside technological innovation, work is also progressing on establishing the standards needed to bring carbon recycling cement to market.

Masayoshi Konishi, Senior Fellow at the Cement & Concrete Research Institute of Sumitomo Osaka Cement, explains:

“Under the current JIS standards, which set the quality and performance criteria for cement, artificial limestone can’t yet be used as an extender. And there’s no standard in place for blended cement made with a mix of CO2 recycling artificial limestone and natural limestone, either. That’s why we’re sharing our experimental data and findings from this project—to help lay the groundwork for establishing those standards.”

These efforts are steadily laying the foundation for full-scale commercialization.

Masayoshi Konishi, Senior Fellow at the Cement & Concrete Research Institute of Sumitomo Osaka Cement

Masayoshi Konishi, Senior Fellow at the Cement & Concrete Research Institute of Sumitomo Osaka CementIn addition to cement applications, the project is also exploring broader uses of CO2 recycling artificial limestone. Several products made with this innovative material—developed using the project’s foundational technologies—have already reached the market.

At the Sumitomo Pavilion at Expo 2025 Osaka, Kansai, visitors can discover a variety of merchandise crafted from this material—including memo pads, postcards, and paper crafts made with CO2 recycling artificial limestone paper, as well as clear folders produced using resin blended with the same substance.

Elsewhere, road marking paint partially formulated with CO2 recycling artificial limestone has been adopted for use on access roads leading to the Expo venue. Sumitomo Osaka Cement is also actively working to apply this material to semi-flexible pavement solutions in the field of road paving.

Sumitomo Osaka Cement is moving forward with plans to optimize its production process using a newly completed pilot facility, aiming to establish technology capable of producing up to 270 tons of CO2 recycling artificial limestone annually by fiscal year 2028. Around that time, a scaled-up facility is expected to be operational, enabling annual output to reach approximately 2,700 tons. The company envisions a full-scale commercial plant with an annual production capacity of 700,000 tons by fiscal year 2040—and is steadily building the technological expertise needed to bring that vision to fruition.

Looking ahead, the newly completed pilot facility will serve as a vital platform for advancing to the next stage: scaling up production. To ensure long-term viability, efforts are now focused on streamlining the system and reducing costs—since simply enlarging the current setup could lead to an unwieldy facility, with inflated construction expenses and operational inefficiencies.

While much of the process relies on chemical reactions that require little to no external energy, one critical exception is the Bipolar Membrane Electrodialysis (BMED) stage, which demands significant electricity. Currently, this power is supplied through on-site biomass generation. As the project moves toward commercial-scale deployment, the team is actively exploring optimal operating conditions to enhance the energy efficiency of the BMED process.

Koji Kawamata of NEDO (left); Noriyuki Kozakai of Sumitomo Osaka Cement with a clear file (center); and Masayoshi Konishi with a memo pad (right)—both made with CO2 recycling artificial limestone.

Koji Kawamata of NEDO (left); Noriyuki Kozakai of Sumitomo Osaka Cement with a clear file (center); and Masayoshi Konishi with a memo pad (right)—both made with CO2 recycling artificial limestone.- *Note The CO2 recycling artificial limestone pilot-scale facility occupies a site area of 628.77 m2 and houses equipment for five main process stages: calcium extraction (via acid leaching), water treatment, mineralization, BMED (Bipolar Membrane Electrodialysis), and gas absorption. The CO2 used in the artificial limestone production process is recovered from flue gas emitted by the cement plant located within the same Tochigi Plant site, and is transported to the pilot facility via several hundred meters of pipeline.

In the calcium extraction stage, calcium is extracted from waste materials by dissolving them in hydrochloric acid (HCl), yielding a calcium-containing solution. The water treatment stage reduces impurities in this solution by adding an alkaline agent (NaOH or KOH) to adjust the pH, causing non-calcium components to precipitate. This increases the calcium purity. According to Noriyuki Kozakai, Managing Executive Officer at Sumitomo Osaka Cement, the process involves repeated pH adjustments to efficiently remove specific elements.

The purified calcium solution is then used in the mineralization stage, where it reacts with sodium carbonate (Na2CO3)—generated from recovered CO2—to form CO2 recycling artificial limestone. The sodium carbonate is produced in the gas absorption stage by reacting flue gas from the cement plant with externally supplied alkaline solution. This process captures over 90% of the CO2 present in the exhaust.

The hydrochloric acid used in the calcium extraction stage and the alkaline solutions used in both the water treatment and gas absorption stages are generated via the BMED process. This involves separating and decomposing the liquid residue—obtained after the mineralization stage removes the artificial limestone—from the remaining slurry using a bipolar membrane electrodialysis system.

Kozakai notes that the entire sequence is based on basic chemical reactions, and once the technology is fully established, it can be implemented on-site with relative speed. He emphasizes that this represents a critical development for companies in the concrete and cement industries, where reducing CO2 emissions is imperative—and that the social implementation of CO2 recycling artificial limestone is now within reach.