On April 24, 2025, the New Energy and Industrial Technology Development Organization (NEDO), in collaboration with Yanmar Energy System and JA Gifu (Gifu Agricultural Cooperative), launched the first pilot unit of a high-efficiency rice husk biochar production system. Installed at the JA Gifu Katagata Country Elevator facility*1 in Gifu City, the system was unveiled at a formal ceremony, marking the beginning of a demonstration phase designed to verify its performance and potential for broader deployment.

The ribbon-cutting ceremony. The high-efficiency rice husk biochar production system is visible on the right.

The ribbon-cutting ceremony. The high-efficiency rice husk biochar production system is visible on the right.This demonstration project is part of NEDO’s Green Innovation (GI) Fund initiative, specifically within the program for the development of technologies to reduce and sequester CO₂ in the food, agriculture, forestry, and fisheries sectors. It represents one of the efforts to reduce carbon emissions in the agricultural domain.

Rice husks and biochar. Compared to the original rice husks, the resulting biochar weighs approximately 30% as much and occupies 40–50% of the original volume. To prevent it from becoming airborne during agricultural application, moisture is added before spreading.

Rice husks and biochar. Compared to the original rice husks, the resulting biochar weighs approximately 30% as much and occupies 40–50% of the original volume. To prevent it from becoming airborne during agricultural application, moisture is added before spreading.The demonstration project is being led by the High-Functional Biochar Consortium, which consists of Gurunavi, Inc. (serving as the lead organization), the National Federation of Agricultural Cooperative Associations (JA Zen-Noh), Katakura & Co-op Agri Corporation, Yanmar Energy System Co., Ltd., and the National Agriculture and Food Research Organization (NARO).

Over a six-year period ending on March 31, 2031, the consortium aims to reduce the cost of biochar production and conduct field trials across more than 50 regions in Japan. These trials will focus on applying high-functional biochar enhanced with beneficial microorganisms that promote plant growth and other positive effects.*2

- *1 A country elevator is a large-scale facility jointly used by multiple grain-producing farmers for drying, storage, conditioning, and shipping of harvested crops.

- *2 According to the guidelines of the Intergovernmental Panel on Climate Change (IPCC), biochar is defined as a solid material generated by heating biomass to a temperature in excess of 350°C under conditions of controlled and limited oxidant concentrations to prevent combustion. It has been recognized for its capacity to sequester carbon in soil.

Establishing an Effective Technology for Achieving Carbon Negativity

The newly unveiled pilot system utilizes rice husks—an abundant agricultural byproduct—as its raw material to produce biochar more efficiently than conventional methods.

Koji Yamashita, President of Yanmar Energy System, the company that developed the pilot unit

Koji Yamashita, President of Yanmar Energy System, the company that developed the pilot unitKoji Yamashita, President of Yanmar Energy System, which developed the unit, emphasized the urgency of action, stating:

“Achieving carbon neutrality by 2050 is no longer optional—it is imperative. Energy conservation and renewable energy adoption alone will not suffice; we also need technologies that actively enable carbon negativity, where greenhouse gas absorption exceeds emissions.

Biochar is precisely such a technology. To promote its nationwide adoption, it is essential to reduce production costs. We are currently developing a system that achieves a 20% improvement in biochar yield over our previous models.”

Takeshi Matsumoto, Chief of the Component Group in the Technology Development Department at Yanmar Energy System, responsible for developing the biochar production system

Takeshi Matsumoto, Chief of the Component Group in the Technology Development Department at Yanmar Energy System, responsible for developing the biochar production systemRegarding specific targets, Takeshi Matsumoto, Chief of the Component Group in the Technology Development Department at Yanmar Energy System, explained:

“Previously, we produced 25 kilograms of biochar per 100 kilograms of rice husks processed per hour. By minimizing the loss of carbon during combustion, we aim to increase the output to 30 kilograms—achieving 120% of our previous yield.

We are also targeting a reduction in production costs from ¥50,000 to ¥30,000 per ton of biochar.”

Matsumoto further noted that burying rice husks can generate methane gas, which has a higher global warming potential than carbon dioxide, while open burning causes issues such as smoke and odor. He highlighted three key advantages of the pilot unit:

1. It is clean, producing no smoke or odor;

2. It requires minimal cleaning and maintenance;

3. It enables the production of high-quality biochar.

Automated bagging system for the finished biochar. Each bag holds 70–75 kilograms of biochar and fills up in two to three hours.

Automated bagging system for the finished biochar. Each bag holds 70–75 kilograms of biochar and fills up in two to three hours.Matsumoto elaborated as follows:

“The system ignites rice husks using an electric heater, without relying on fossil fuels. It then utilizes the energy contained in the husks themselves to sustain combustion at temperatures exceeding 800°C, resulting in clean exhaust emissions.

The unit is fully automated and requires only minimal operator input. Thanks to its low-noise design, it can run continuously for 24 hours, including nighttime operation. In addition, the system features automatic bagging, making it virtually maintenance-free.

Because the combustion temperature is higher than that of conventional biochar production methods, the resulting biochar tends to have numerous fine pores. These pores help retain nutrients and moisture and also provide a favorable environment for beneficial microorganisms to inhabit.”

Field Trials of the First High-Functional Biochar to Begin in 2025

The newly introduced pilot unit is designed to produce base biochar, which serves as the foundation for high-functional biochar. By mixing the biochar with beneficial microorganisms, it becomes a value-added material that can promote healthy crop growth by aiding the decomposition of organic matter in the soil and suppressing harmful pathogens.

Shori Yamamoto, Ph.D., Director at the Institute for Agro-Environmental Sciences, National Agriculture and Food Research Organization (NARO)

Shori Yamamoto, Ph.D., Director at the Institute for Agro-Environmental Sciences, National Agriculture and Food Research Organization (NARO)Shori Yamamoto, Ph.D., Director at the Institute for Agro-Environmental Sciences, National Agriculture and Food Research Organization (NARO), which is leading the enhancement of biochar functionality, explained:

“There are many options when it comes to the materials and techniques used to enhance biochar. The most effective combination depends on the crops being cultivated and the specific soil conditions. We are currently working with Katakura & Co-op Agri Corporation to develop materials for this purpose.

Beginning in 2025, we are conducting regional trials in actual fields, with the cooperation of local farmers, to evaluate these technologies under real-world conditions. Our long-term vision is to establish a local-production-for-local-consumption system in which rice husks from local paddy fields are converted into biochar and retained within the region.

I also understand that JA Gifu is planning a demonstration project involving biochar application in 'Yuki-no-Sato' (an Organic Farming Village) in Gifu City, where efforts to promote environmental friendly and sustainable agriculture are underway.”

Biochar Field Trials to Start in 50 Regions, Expand to 100 beyond FY2031

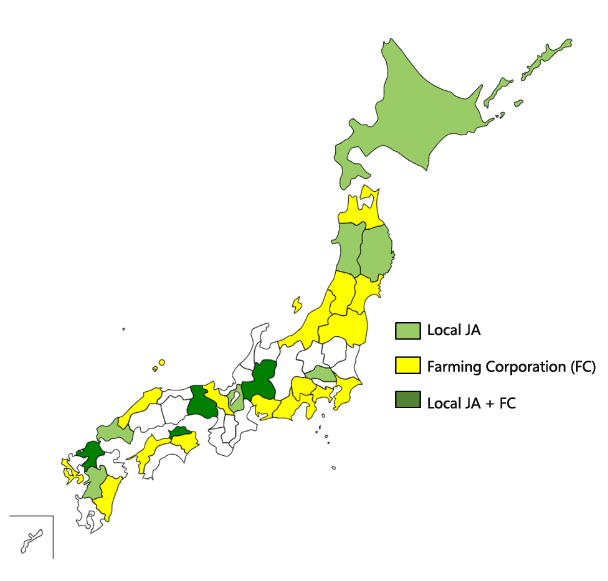

Field trials involving the application of high-functional biochar and crop cultivation tests are scheduled to begin in fiscal year 2025. The trials will be conducted in more than 50 agricultural sites across Japan, in collaboration with Japan Agricultural Cooperatives (JA) and farming corporations.

Fifty trial sites have been selected for FY2025 and beyond to conduct biochar application and cultivation tests. Source: "The 29th Working Group on Industrial Restructuring (January 30, 2025)" with updates from Gurunavi’s presentation.

Keiko Fuchigami, Director of the Frontier Department and Project Manager of the GI Fund Project (Development of Negative Emissions Technologies in Agriculture, Forestry, and Fisheries Industries)at NEDO

Keiko Fuchigami, Director of the Frontier Department and Project Manager of the GI Fund Project (Development of Negative Emissions Technologies in Agriculture, Forestry, and Fisheries Industries)at NEDOKeiko Fuchigami, Director of the Frontier Department and Project Manager of the GI Fund Project at NEDO explained the overall plan as follows:

“To utilize high-functional biochar in the 50 designated regions, we plan to operate the biochar production units for 4,000 hours annually, converting 400 tons of rice husks into 120 tons of biochar. Assuming an average of 0.1 hectares (10 ares) per region, we intend to supply approximately 200 kilograms of biochar to each site. (Note: Some crops may be grown on fields as large as 0.3 hectares.)

Going forward, we aim to expand the number of regions in stages, reaching over 100 sites nationwide after FY2031. Our goal is to produce 10,000 tons of biochar annually, resulting in a CO₂ reduction of an equivalent 10,000 tons.”

Fuchigami emphasized that while the immediate priority is to optimize the first biochar production unit, scaling up production will be essential to meet nationwide demand.

“We plan to install additional units, aiming to establish a ten-unit system by FY2030,” she noted, outlining the project’s future direction.

In the demonstration trials of high-functional biochar, the team will not only examine its effects on crops and soil but also work on developing application techniques to reduce spreading costs.

Making the Environmental Value Clear to Consumers

Effectively communicating the environmental value of high-functional biochar to consumers is a key factor in promoting its widespread adoption in society.

Gurunavi is playing a central role in the consortium's efforts to explore how to convey the added value of agricultural products grown using high-functional biochar in a way that is understandable to consumers.

Kenji Hamaya, Section Manager of the GI Business Promotion Section in Gurunavi’s Green Innovation Business Promotion Department

Kenji Hamaya, Section Manager of the GI Business Promotion Section in Gurunavi’s Green Innovation Business Promotion DepartmentKenji Hamaya, Section Manager of the GI Business Promotion Section in Gurunavi’s Green Innovation Business Promotion Department, explained:

“We are currently developing an Environmental Value Assessment System in which farmers can input data such as the type and timing of the crops they grow, as well as the amounts of high-functional biochar and fertilizers used. The system will then quantify the environmental value of the products. We are also examining how best to communicate this value to consumers in a clear and accessible way. In addition to conducting consumer surveys, we are planning trial sales to test these approaches.”

Gurunavi has previously conducted surveys of consumers who purchase environmentally friendly agricultural products such as organically grown produce. The results indicated that cultivation method was not the primary motivation for purchase. Regardless of age, respondents were more likely to cite concerns about health and safety, or a desire to support local production regions.

Building on this insight, Gurunavi is now working to develop consumer personas—hypothetical profiles that help identify which demographic groups to target and how to effectively market the products to them.

In addition to the technical aspect of biochar’s carbon sequestration potential, a key research focus is how to communicate its environmental value in ways that resonate with consumers.

Tetsuji Iwasa, President, JA Gifu

Tetsuji Iwasa, President, JA GifuTetsuji Iwasa, President, JA Gifu, expressed his appreciation, stating:

“We thank Gurunavi for helping us connect with Yanmar Energy System. That connection made it possible to introduce high-functional biochar here in Gifu. Amid the decline in the number of people working in agriculture, we hope to protect and sustain regional farming by focusing on producing what consumers truly want.”

R&D Progressing Steadily in Fisheries and Forestry

Tomoyasu Nishimura, Executive Director at NEDO

Tomoyasu Nishimura, Executive Director at NEDOTomoyasu Nishimura, Executive Director at NEDO, provided an overview of the project, stating:

“As an innovation accelerator, we are advancing the resolution of social issues by pursuing ambitious R&D and demonstration initiatives aimed at addressing global energy and environmental challenges while strengthening Japan’s industrial technological capabilities.

Within the Project for the Development of CO₂ Reduction and Sequestration Technologies in the Food, Agriculture, Forestry, and Fisheries Sectors, we are working on three key areas:

– Blue carbon sequestration in the ocean through the creation and restoration of seaweed beds using seaweed cultivation blocks;

– Promoting the use of domestic timber and urban carbon storage through the development of wood-based isotropic large-scale cross-sectional structural members for high-rise wooden buildings;

– And today's focus: carbon sequestration in cropland and enhanced agricultural profitability through high-functional biochar.

Together, these initiatives represent a comprehensive approach that spans agriculture, forestry, and fisheries.”

He also emphasized the significance of MAFF’s (Ministry of Agriculture, Forestry and Fisheries) involvement, noting that:

“Out of the 20 projects supported by the GI Fund, this is the only one involving MAFF. With the ministry’s participation, JA organizations have been able to engage in the initiative, ensuring that farmers directly benefit from its outcomes.”

Akihiro Higashino, Deputy Director General, Agriculture, Forestry and Fisheries Research Council, MAFF

Akihiro Higashino, Deputy Director General, Agriculture, Forestry and Fisheries Research Council, MAFFAkihiro Higashino, Deputy Director General, Agriculture, Forestry and Fisheries Research Council, MAFF, stated:

“MAFF is conducting R&D based on the MIDORI Strategy for Sustainable Food Systems, which aims to achieve both enhanced productivity and sustainability in the food, agriculture, forestry, and fisheries sectors through innovation. As part of this strategy, we are also working on the development of supply and utilization technologies for high-functional biochar.”

Fuchigami, the project manager overseeing the entire initiative, also shared updates on progress beyond the agricultural sector:

“Our blue carbon project—focused on the sequestration and storage of carbon in marine ecosystems such as seaweed beds—is currently in the intermediate cultivation phase. In this phase, young seaweed is grown under controlled conditions until it becomes resilient to environmental changes. To support this, 1,000 seaweed cartridges (plates with planted seaweed) have been installed at each of five fishing ports nationwide, totaling 5,000 units,” she said.

As for the development of wood-based isotropic large-scale cross-sectional structural members aimed at promoting the use of domestic timber in high-rise wooden buildings, she continued, “The project is progressing according to milestones. We plan to begin development of a continuous production line in fiscal year 2025.”

In-addition to the R&D efforts in the agricultural sector presented in this report, NEDO will continue to accelerate research and development in the fisheries and forestry sectors under the GI Fund Project, focusing on the development of technologies to reduce and sequester CO₂ in the food, agriculture, forestry, and fisheries industries.