Research on CO2 capture and separation is making steady progress in Japan. As part of its Green Innovation (GI) Fund Project, NEDO is working to develop technologies that can capture CO2 from low-concentration (less than 10%) and low-pressure flue gas emitted by factories and other sources. One of the participating companies, Air Water Inc., has now launched a demonstration of its CO2 capture and separation system at Expo 2025 in Osaka.

The company has installed its CO2 capture and separation system at the Expo site. The recovered CO2 is liquefied and purified to a high concentration, then used to produce dry ice for cooling purposes within the venue. Part of the captured CO2 is also sent to a methanation facility operated by Osaka Gas, where it reacts with hydrogen to produce methane. This methane is then used as city gas in the Expo’s kitchens and heating systems.

Air Water’s CO2 capture and separation system, Chikyu no Megumi Station, installed at Expo 2025 Osaka, Kansai. Located inside the Carbon Recycling Factory at the Expo venue, the system captures CO2 from combustion flue gas supplied from the left side of the photo, with the main recovery unit shown at the center. The system uses four CO2 absorption towers.

Air Water’s CO2 capture and separation system, Chikyu no Megumi Station, installed at Expo 2025 Osaka, Kansai. Located inside the Carbon Recycling Factory at the Expo venue, the system captures CO2 from combustion flue gas supplied from the left side of the photo, with the main recovery unit shown at the center. The system uses four CO2 absorption towers.As CO2 Capture Gains Momentum Worldwide, Japan Pushes Forward

The global market for carbon dioxide capture and storage (CCS) is expanding rapidly. In the United States, tax incentives under the Inflation Reduction Act (IRA) are strongly supporting projects that store captured CO2 underground. European countries are also promoting CCS as part of their national strategies, further intensifying international competition. In particular, Europe is focusing on applying CO2 capture and separation technologies to hard-to-abate sectors—industries such as steel, chemicals, cement, and pulp and paper, where emissions are especially difficult to reduce. These sectors are considered difficult to decarbonize, as renewable energy and hydrogen cannot easily replace conventional energy sources. At the same time, global interest is growing in carbon dioxide capture and utilization (CCU), which aims to treat captured CO2 as a valuable resource.

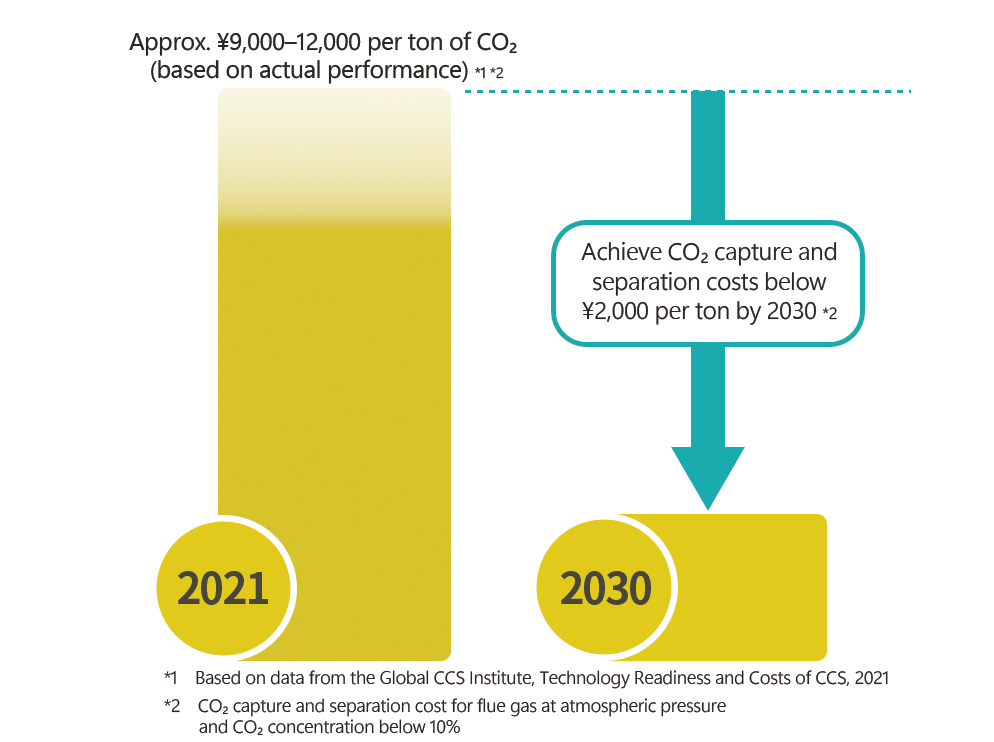

To keep pace with these global trends, Japan is also accelerating the development of CO2 capture and separation technologies. Under its Green Innovation (GI) Fund Project, NEDO has set an ambitious goal: to reduce CO2 capture and separation costs to the 2,000-yen range per ton by 2030.

Goal to reduce CO2 capture and separation costs

Goal to reduce CO2 capture and separation costs“Despite rising costs for equipment and materials, we remain committed to achieving this ambitious target. To that end, we are advancing projects under seven thematic areas through the GI Fund initiative,” says Masaaki Oki,Green Innovation Fund Project Manager (CO2 Separation, Capture) at NEDO. Given that the current cost of CO2 capture and separation exceeds ¥10,000 per ton, this goal is particularly challenging.

Masaaki Oki, Green Innovation Fund Project Manager (CO2 Separation, Capture) at NEDO

Masaaki Oki, Green Innovation Fund Project Manager (CO2 Separation, Capture) at NEDOConventional CO2 capture and separation technologies were originally developed overseas to enhance oil recovery. In these applications, captured CO2 was injected into oil fields to increase reservoir pressure and boost crude oil output. The CO2 in these applications typically came from high-pressure, high-concentration gas streams.

These technologies were later adapted to address climate change, with applications shifting toward capturing CO2 from flue gas emitted by thermal power plants. Flue gas from coal-fired power plants, which contains about 14% CO2, allowed for relatively low-cost recovery.

However, capturing CO2 from low-pressure flue gas with low CO2 concentrations—around 4% in the case of natural gas power plants—is technically challenging and significantly more expensive.

NEDO’s goal is to dramatically reduce the cost of capturing and separating CO2 from flue gas with low concentration and low pressure. The initiative targets not only natural gas power plants, but also combustion exhaust from boilers used across various industrial facilities.

Achieving this goal would significantly expand the range of industries capable of implementing CO2 capture technologies. To meet the target, it is essential to accelerate technological development and bring these solutions to market ahead of schedule.

Breakthrough CO2 Capture with Na–Fe-Based Solid Absorbent

Traditionally, CO2 capture technologies have relied primarily on two approaches: liquid amine scrubbing, which uses amine-based liquids (containing amino groups) to absorb CO2, and pressure swing adsorption (PSA), which recovers CO2 by manipulating pressure levels. In contrast, the system installed by Air Water at the Expo applies a temperature swing absorption method, which selectively captures CO2 by controlling the temperature of the absorbent.

Although temperature swing gas separation technologies have long been used in various gas purification processes, their application for CO2 capture has been limited. This is primarily due to the low CO2 capture capacity per unit of absorbent material and the high thermal energy required for regeneration, both of which contribute to higher CO2 capture costs.

The absorbent used by Air Water is a newly developed solid material based on Na–Fe-based oxide, created in collaboration with Saitama University and TODA KOGYO. This material overcomes key drawbacks of conventional temperature swing methods. By leveraging a chemical reaction between the absorbent components and CO2, it significantly improves both the CO2 capture volume and absorption rate per unit of material. In addition, it enables CO2 to be released at lower temperatures compared to conventional materials, reducing the thermal energy required for regeneration. Its ability to efficiently capture CO2 even at low concentrations makes it particularly well-suited for flue gas from boilers and other combustion sources—the primary targets of this technology.

Makoto Terai, General Manager, Plant & Equipment Development Center at Air Water, which is overseeing the demonstration project, explains the strengths of the current facility:

“Capturing and separating CO2 typically requires a large amount of thermal energy. By making effective use of waste heat, however, we can reduce the need for additional electricity and steam as heat sources. This is expected to significantly lower overall energy consumption—and it’s a key factor in reducing CO2 capture costs.”

Makoto Terai, General Manager, Plant & Equipment Development Center, Air Water Inc.

Makoto Terai, General Manager, Plant & Equipment Development Center, Air Water Inc. Solid absorbent used in the Chikyu-no-Megumi Station, shown here in black pellet form.

Solid absorbent used in the Chikyu-no-Megumi Station, shown here in black pellet form.“The demonstration at the Expo aims to evaluate key performance targets: a CO2 recovery rate of 0.3 tons per day (TPD), a recovery purity of over 98%, and electricity consumption of 0.1 kWh per kilogram of CO2 captured,” says Terai. These targets serve as critical benchmarks on the path toward commercialization.

After the Expo, the CO2 capture unit installed at the venue will be modified and scaled up for continued demonstration testing at TODA KOGYO’s facility in fiscal 2026. Through this extended testing, the team will assess durability and operational stability, as well as identify challenges associated with scaling up—further refining the technology.

Building on the results of the Expo demonstration, Air Water aims to commercialize the technology starting in fiscal 2027. While rising material and equipment costs have made it more challenging to meet cost targets, market demand remains strong.

“We’ve received inquiries from a wide range of industries—including automakers, chemical manufacturers, logistics and shipping companies, and even beverage and food producers,” says Terai. “There’s growing interest in CCU, not just for storing captured CO2, but for reusing it across diverse industrial sectors.”

Captured CO2 has numerous practical applications—from serving as a feedstock for synthetic fuels and producing dry ice and chemicals, to enhancing crop growth. As demand grows from industries facing CO2 shortages and companies looking to recycle their own emissions, interest in CO2 capture and separation technologies continues to rise. Air Water’s technology is well-positioned to support this momentum and help unlock new market opportunities.

Masaaki Oki, Project Manager of the GI Fund Project and Makoto Terai, General Manager, Plant & Equipment Development Center at Air Water

Masaaki Oki, Project Manager of the GI Fund Project and Makoto Terai, General Manager, Plant & Equipment Development Center at Air WaterFast-tracking CO2 Capture Tech to Build a New Industrial Future

Oki, who leads NEDO’s efforts in this area, shared his thoughts on accelerating the development and deployment of CO2 capture and separation technologies:

“Efforts to commercialize CO2 capture and separation technologies under the GI Fund project are not limited to Air Water. DENSO and Toho Gas are moving ahead of schedule for their technology development. DENSO, for instance, is working on a CO2 capture and separation system for factory flue gas and has brought forward its Stage Gate review from the end of FY2026 to the end of FY2025, signaling a strong commitment to early implementation. Toho Gas is developing a CO2 capture and separation system for emissions from city gas combustion and has begun some activities ahead of schedule to accelerate progress. In addition, Sumitomo Chemical plans to launch a new demonstration project for CO2 capture and separation in FY2026 and has already started preparations in FY2025. These initiatives reflect Japan’s proactive response to the growing global market for CO2 capture and separation technologies, and we at NEDO have been working closely with private-sector partners to facilitate these developments.”

“Through these demonstration projects, we aim to accelerate the early establishment and social implementation of CO2 capture and separation technologies—strengthening Japan’s industrial competitiveness and advancing the realization of a decarbonized society. As companies continue to develop and test their technologies in coordination, the successful establishment of low-cost, high-efficiency CO2 capture solutions would not only help Japan meet its emissions reduction targets, but also position the country as a global leader in the decarbonization movement. Our goal goes beyond responding to climate change—it’s about creating new industries and driving future economic growth. We will continue pushing the project forward with this vision in mind.”

Note: Titles are as of July 2025, at the time of interview.