Offshore wind power is gaining worldwide attention as one of the most promising renewable energy sources. As turbines grow larger, their bearings—core components of the system—face increasing demands for both performance and maintainability. Addressing this challenge is a key focus for NEDO.

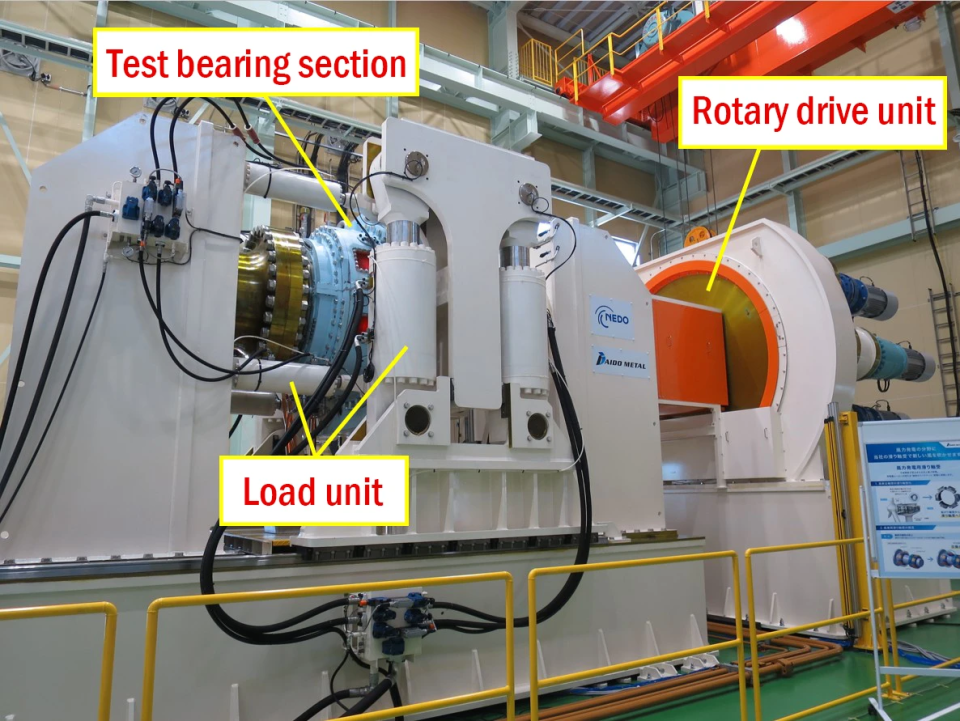

Through its Green Innovation (GI) Fund Projects, “Cost Reductions for Offshore Wind Power Generation,” NEDO is supporting efforts to advance bearing technology. As part of the project, Daido Metal Co., Ltd. has developed a groundbreaking bench test rig for plain bearings used in turbine main shafts. The rig was installed at Daido Metal Saga’s facility in Takeo City, Saga Prefecture, and began operation at the end of April 2025.

Plain bearings form an oil film between the shaft and the bearing surface, allowing the shaft to slide smoothly. Unlike conventional ball or roller bearings, this design follows a different principle. It combines high performance with easier maintenance, making it a strong candidate for next-generation offshore turbines. With the new test rig now in operation—able to test bearings under conditions close to actual wind turbine use—the path toward applying fluid-film plain bearings in offshore wind turbines has advanced significantly.

Bench test rig for plain bearings

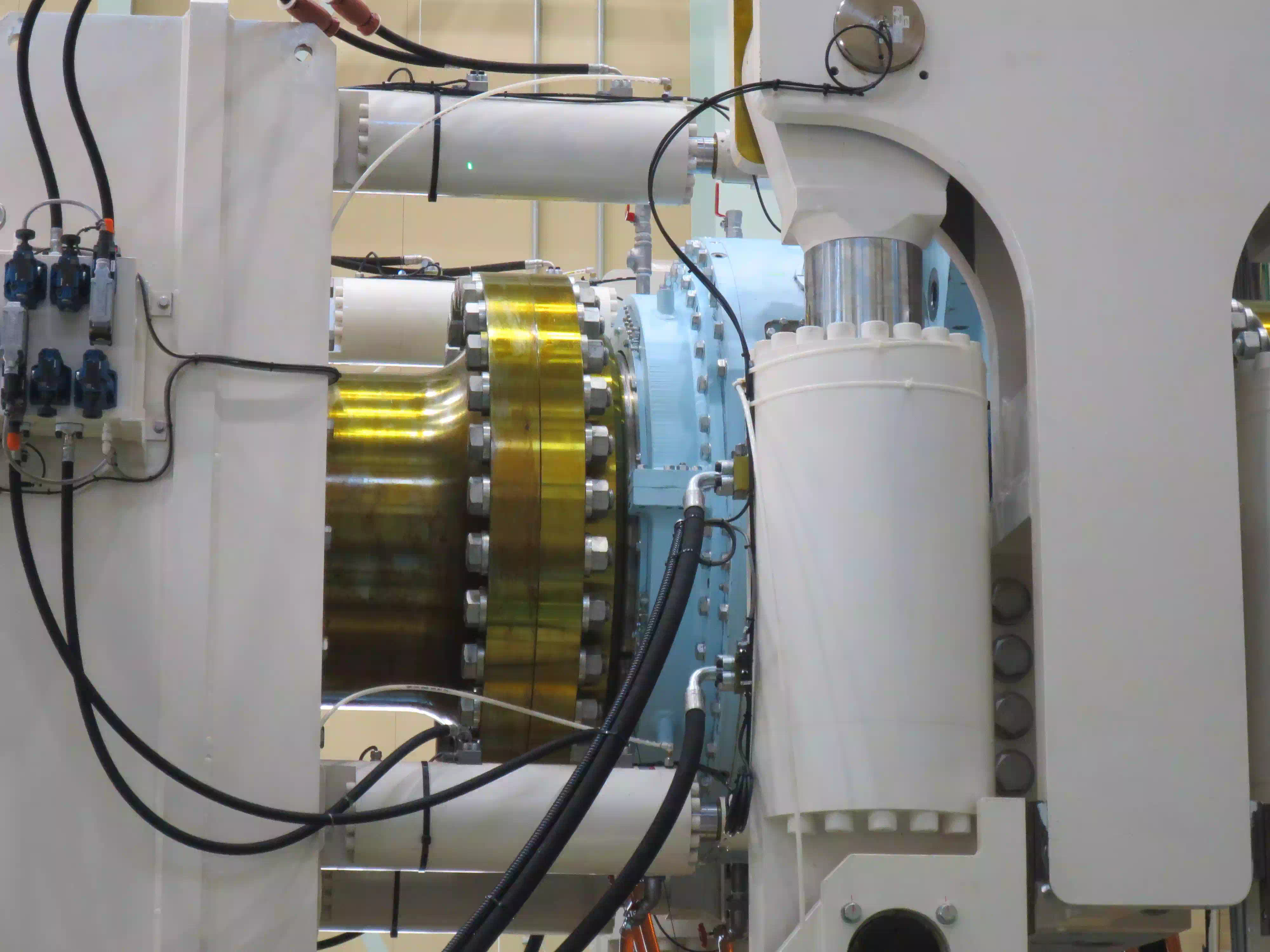

Bench test rig for plain bearings Bearing assembly unit of the test rig (light blue, right of center), housing the test bearing

Bearing assembly unit of the test rig (light blue, right of center), housing the test bearingSplit-Type Plain Bearings Offer a Solution

The expansion of offshore wind power depends heavily on larger turbines, which are seen as the key to improving power generation efficiency. Shunsuke Saegusa, Director of the Wind and Marine Unit, Renewable Energy Department at NEDO, explains:

“In Japan, the largest offshore turbines currently in operation are rated at 9.6 MW. From 2029 onward, however, turbines in the 12 to 15 MW class are expected to become the global standard. Larger turbines generate more electricity per unit, making more efficient use of limited sea areas. At the same time, though, several new challenges emerge.”

Shunsuke Saegusa, Director of the Wind and Marine Unit, Renewable Energy Department at NEDO

Shunsuke Saegusa, Director of the Wind and Marine Unit, Renewable Energy Department at NEDOAccording to Saegusa, the specific challenges are as follows.

First, the larger size and heavier weight of components create manufacturing difficulties. In addition, the operating loads increase significantly, placing greater stress on each component and raising the risk of failure. Bearings, in particular—critical components of the turbine—bear the heaviest loads, and their reliability directly affects overall availability.

Maintenance of larger turbines is also far more challenging than for smaller ones. Unlike onshore turbines, offshore maintenance requires costly crane operations, and in the worst case, the top of the turbine may need to be dismantled, shipped back to land for repair, and then reinstalled offshore. Such procedures can cost hundreds of millions of yen and keep turbines offline for one to two months, or even longer. To address these issues, it is essential to develop components that are easier to manufacture and reduce maintenance costs.

One promising solution is the split-type plain bearing now under development by Daido Metal Co., Ltd. “Rather than replacing the entire nacelle or its main components such as the blades,” Saegusa explains, “the new bearing is designed so that the main shaft bearing can be slid out and replaced in sections. This makes it possible to carry out maintenance on-site, greatly reducing both time and cost.”

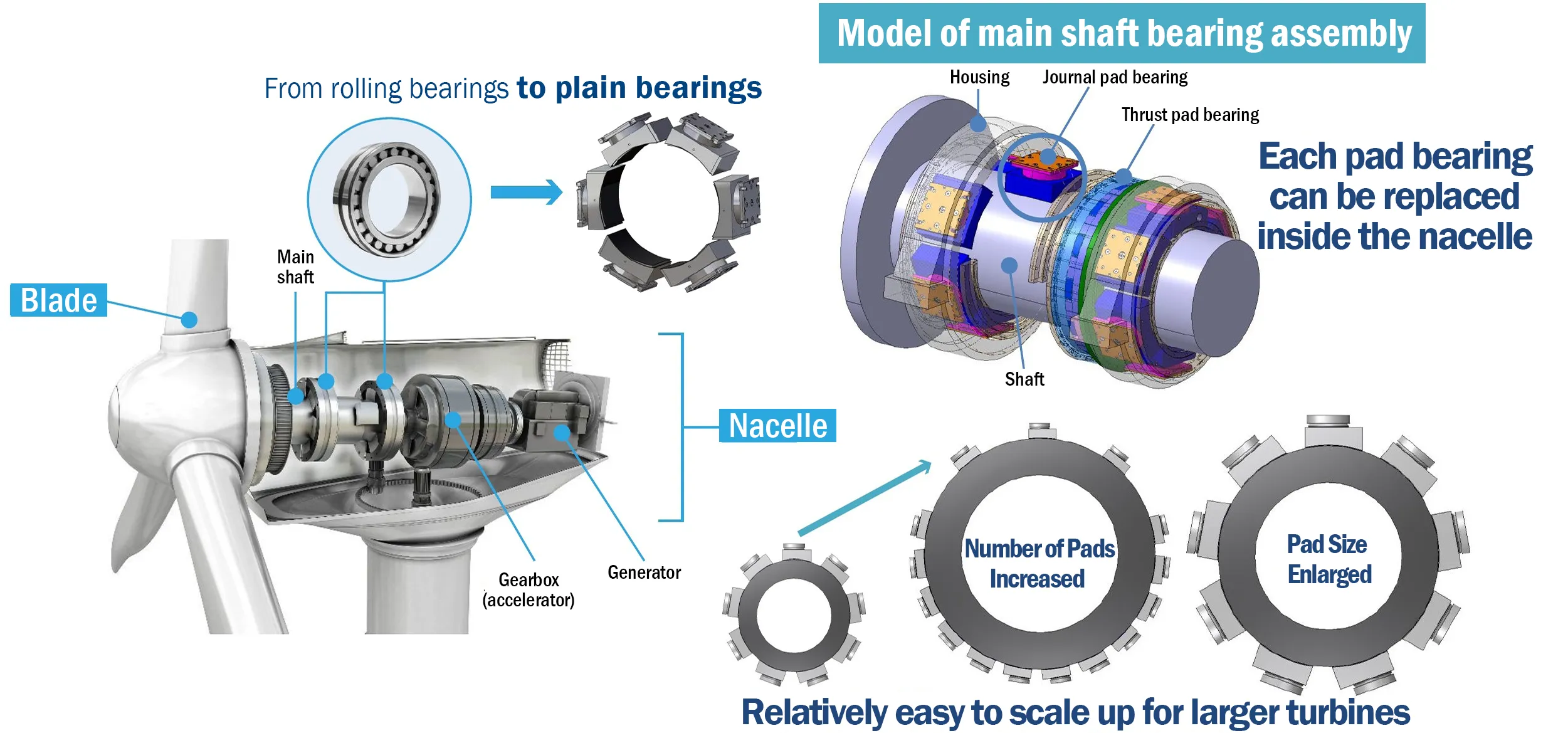

Advantages of Plain Pad Bearings (Source: Daido Metal Co., Ltd.)

Advantages of Plain Pad Bearings (Source: Daido Metal Co., Ltd.)The main advantages of the plain bearings proposed by Daido Metal Co., Ltd. are their ease of maintenance and the relative simplicity of manufacturing them for larger turbines. Because they are of a split type, the components can be slid out and replaced inside the nacelle. As mentioned earlier, this eliminates the need for large offshore cranes and extensive dismantling and reinstallation work, greatly improving maintenance efficiency.

Another advantage is that, while rolling-element bearings have an integral ring structure, plain bearings can be scaled up relatively easily by increasing the number of pads. In addition, because they use oil, they can absorb the dynamic loads applied by the turbine more effectively through the oil’s damping effect. The application of special resin-based materials to the sliding surfaces also provides excellent insulation in the event of a lightning strike.

Commenting on how Daido Metal succeeded in developing pads with superior insulating properties, Nobutaka Hiramatsu, Managing Executive Officer, Head of Turbo Machinery Bearing Systems Division, and Director of the Wind Turbine Technology R&D Institute, explained:

“It was made possible by leveraging our proprietary composite technology, developed over many years, for bonding polymer and metal.”

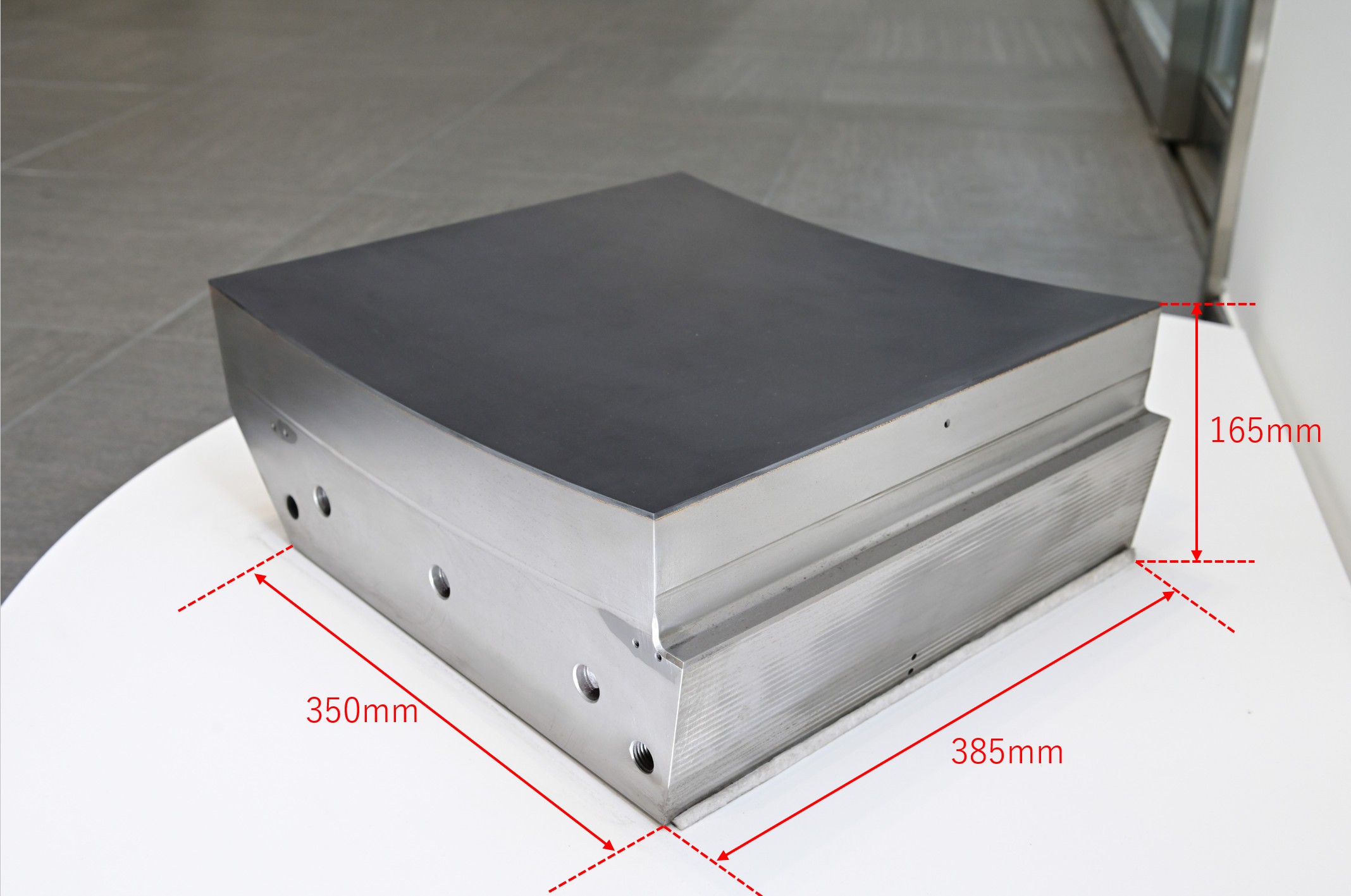

Pad bearing for wind turbine main shaft developed with composite technology

Pad bearing for wind turbine main shaft developed with composite technology Nobutaka Hiramatsu, Managing Executive Officer, Head of Turbo Machinery Bearing Systems Division, and Director of the Wind Turbine Technology R&D Institute, Daido Metal Co., Ltd.

Nobutaka Hiramatsu, Managing Executive Officer, Head of Turbo Machinery Bearing Systems Division, and Director of the Wind Turbine Technology R&D Institute, Daido Metal Co., Ltd.On the other hand, plain bearings have the drawback that no oil film is present at startup, causing the shaft and bearing surfaces to come into contact. As a result, they require higher starting torque compared with rolling-element bearings. To address this issue, improvements in lubricating oil and bearing surface materials are being studied, as well as the possible introduction of startup-assist systems by turbine manufacturers.

The World’s First Test Rig for Plain Bearings

The newly commissioned test rig is an essential tool for developing plain bearings for large wind turbines. Motohira Yamada, General Manager of the Daido Metal TMBS Design Department, Turbo Machinery Bearing Systems Division, who is responsible for bearing design, explained:

“Our focus until now has been on developing the bearing pads—the split components of the bearing. However, turbine manufacturers have increasingly required comprehensive design and development of entire bearing systems. To meet this need, we installed a large-scale test rig at our group company, Daido Metal Saga Co., Ltd., in Saga Prefecture, creating an environment that can simulate the condition of a turbine’s main shaft bearing. This test rig is the world's first bench testing machine specialized for plain bearings, capable of simulating wind turbine operating conditions solely developed by a bearing manufacturer.”

Motohira Yamada, General Manager of the Daido Metal TMBS Design Department, Turbo Machinery Bearing Systems Division

Motohira Yamada, General Manager of the Daido Metal TMBS Design Department, Turbo Machinery Bearing Systems DivisionYamada further noted:

“Conventional rolling-element bearings have been evaluated using test rigs installed individually by bearing manufacturers and turbine manufacturers. While some turbine makers possess large-scale rigs dedicated to plain bearings, until now no bearing manufacturer has had one of its own. By designing and developing reliable plain bearings in-house, and at the same time building our own dedicated test rig, Daido Metal can help turbine manufacturers cut development costs and shorten development timelines. Without this rig, companies would have to rely on European research institutions, incurring significant expense and delays.”

Daido Metal’s project began around 2016, but it faced many challenges and even experienced periods of stagnation. Collaboration with European turbine manufacturers gradually clarified the direction, and participation in the GI Fund Projects provided the momentum that ultimately led to the development of the new large-scale test rig.

The test rig developed this time is designed to match the size and specifications of turbines in the 3 MW to 6 MW class. Data obtained from the rig will be compared with performance analyses modeled on the rig, improving analytical accuracy and enabling application to even larger turbines exceeding 10 MW.

The new rig, the largest ever built in-house, is equipped with a 1-meter-diameter shaft and stands 4.5 meters high. Unlike earlier rigs, which used a shaft of around 50 centimeters in diameter and were limited to laboratory-scale tests, it allows evaluation under conditions much closer to actual turbine operation. A key feature is its ability to reproduce dynamic loads—fluctuating loads that occur during turbine operation.

Over 200 Data Points Measured, Remote Bearing Monitoring Enabled

One of the challenges in using the test rig is verifying the accuracy of the measurement data. Shigeyoshi Mori, Manager of the Technology Group at the Wind Turbine Technology R&D Institute, Daido Metal, explained:

“We analyze more than 200 data points from the sensors in combination, accurately determining oil film thickness, pressure, temperature, and other parameters to confirm bearing function and evaluate performance. In particular, the oil film thickness is extremely thin—less than 0.1 millimeter—so precise measurement is critical.”

Shigeyoshi Mori, Manager of the Technology Group at the Wind Turbine Technology R&D Institute, Daido Metal

Shigeyoshi Mori, Manager of the Technology Group at the Wind Turbine Technology R&D Institute, Daido MetalEstablishing remote monitoring technology is also a key focus. “It is essential to detect signs of abnormalities before failures become apparent and act on them through early intervention, enabling planned maintenance,” explained Mori. “Research to date has already provided a basis for early anomaly detection, and we will now focus on improving its accuracy through verification with the test rig.”

Daido Metal aims to resolve the challenges described above and complete both the development of plain bearings and the evaluation of the test rig by fiscal 2026. Looking ahead, Managing Executive Officer Nobutaka Hiramatsu explained:

“Our goal is to commercialize the technology within fiscal 2027, with offshore wind turbines equipped with plain bearings expected to enter the market around 2029 to 2030. Initially, we plan to supply European turbine manufacturers, with the main applications in offshore wind projects in Europe. In the longer term, however, we also expect adoption in offshore wind power generation in Japan.”

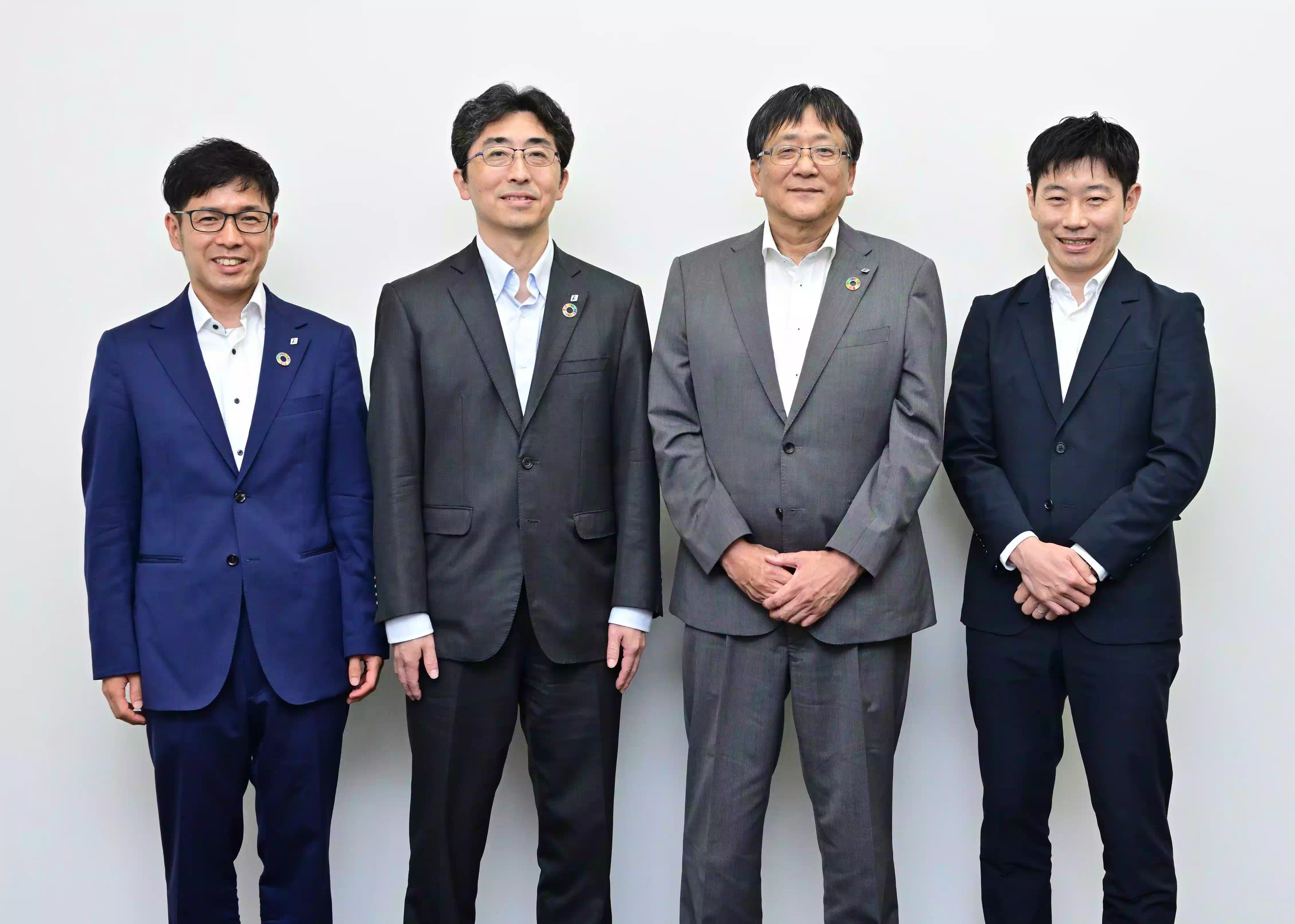

From left: Shigeyoshi Mori, Manager of the Technology Group; Motohira Yamada, General Manager of the TMBS Design Department; and Nobutaka Hiramatsu, Managing Executive Officer, all from Daido Metal. On the far right is Shunsuke Saegusa, Director of the Wind and Marine Unit, Renewable Energy Department, NEDO.

From left: Shigeyoshi Mori, Manager of the Technology Group; Motohira Yamada, General Manager of the TMBS Design Department; and Nobutaka Hiramatsu, Managing Executive Officer, all from Daido Metal. On the far right is Shunsuke Saegusa, Director of the Wind and Marine Unit, Renewable Energy Department, NEDO.Although the offshore wind power sector is currently facing headwinds such as rising material costs, its long-term importance as a renewable energy source remains unshaken. Because renewable energy is inherently variable, it cannot ensure a stable power supply on its own. Going forward, it will be essential to develop grid integration technologies and enhance coordination with other power sources to build a more reliable supply system.

The completion of this new test rig for plain bearings represents a milestone that could allow Japanese technology to help shape the future of offshore wind power worldwide. Through its GI Fund Projects, NEDO will continue to drive technological innovations that strengthen this vital sector.

Titles are as of June 2025, at the time of interview.