*This article is a translation of a Japanese article originally published on September 12, 2025.

Paving the Way to a Carbon-Neutral 2050

NEDO’s Green Innovation Fund (GI Fund) is advancing technology development with a focus on practical implementation to realize a carbon-neutral society. At Expo 2025 Osaka, Kansai, the outcomes of these initiatives are being showcased through demonstration projects. Daily life itself is expected to evolve into a carbon-neutral style—without sacrifice or inconvenience, while maintaining comfort. Step by step, various initiatives are steadily paving the way toward this new era.

The Expo also highlights the outcomes of the GI Fund from five perspectives: Concrete Structures, Mobility, Manufacturing, Power Generation, and Data Centers. This first installment focuses on Concrete Structures and Mobility, with a central theme of reducing CO2 emissions.

■ Toward Carbon-Neutral Concrete Structures

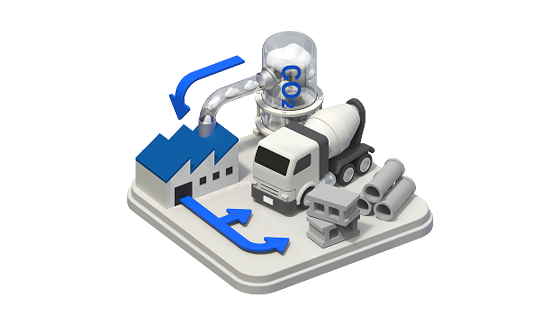

Concrete Structures — including buildings such as homes and offices, as well as infrastructure like bridges and roads—are indispensable to daily life. Yet they emit CO2 not only during use but also during construction. The GI Fund is developing technologies that challenge this premise. Rather than emitting CO2, these innovations harness it as a resource for producing concrete and cement, advancing decarbonization in the construction sector through a genuine reversal of conventional thinking. The achievements showcased at the Expo highlight this new approach, pointing to a future in which, by 2050, CO2 emissions from construction could become a thing of the past.

70% Less CO2 Than Conventional Concrete

In the Future Life Zone of the Expo, several structures have been built using concrete that incorporates CO2 as a resource.

One of the highlights is the Sustainability Dome where CO2 is fixed into the concrete forming the dome itself. Two types of eco-friendly concrete were used: low-carbon ECM Concrete and carbon-negative CUCO-SUICOM Shot, which absorbs and fixes CO2 as it hardens. Together, these technologies achieved about a 70% reduction in CO2 emissions compared with conventional concrete.

Sustainability Dome

Sustainability DomeAt the entrance to the Sustainability Dome, ten types of low-carbon concrete blocks have been installed, including the CUCO-SUICOM Block, which utilizes CO2 directly captured from the atmosphere. These blocks have also been applied to the walkways of the Expo Arena Matsuri. Across the entire installation area of approximately 3,300 m², the use of such blocks reduced CO2 emissions by about 65 tons compared with conventional materials, while additionally fixing about 9.7 tons of CO2 in the concrete.

Concrete is made by mixing cement, sand, gravel, water, and other materials. Cement, being an industrial product, maintains relatively consistent quality across regions, whereas the quality of other materials can vary by location. Given their weight and bulk, these materials are generally sourced locally. For practical application, therefore, the key question is whether CO2 can be reliably absorbed and fixed as designed, even when production takes place in different regions. At the Expo, the construction of the Sustainability Dome demonstrated that such environmentally conscious concrete can indeed be produced with consistent quality in Osaka.

Pavement at the entrance to the Sustainability Dome

Pavement at the entrance to the Sustainability Dome Expo Arena

Expo Arena3 Tons of CO2 Captured During Production

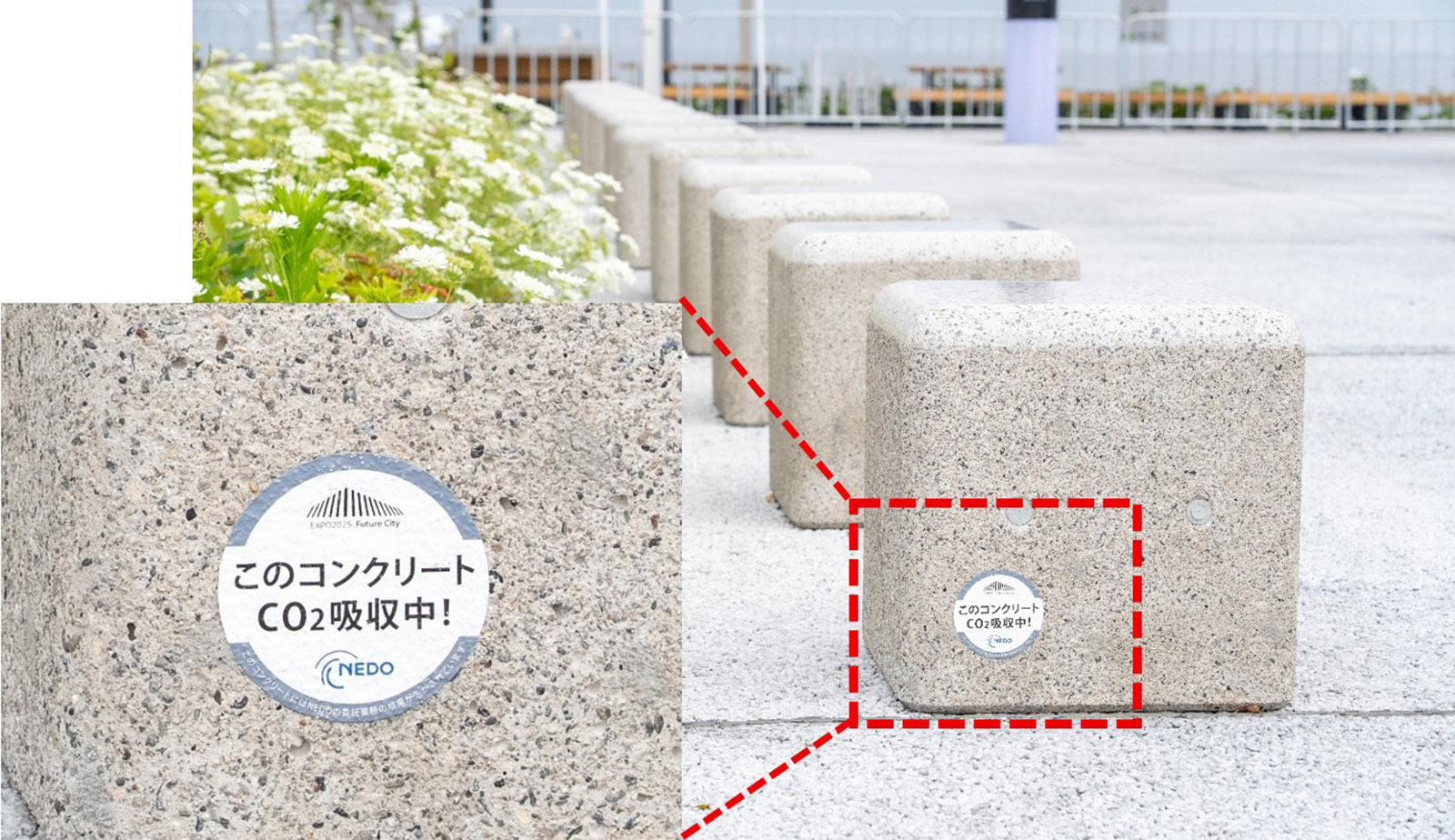

At the “Future City” Pavilion in the Expo’s Future Life Zone, eco-friendly Carbon Pool Concrete (CP Concrete) has been used both inside and outside. This material not only absorbs and fixes CO2 but also makes effective use of by-products from fresh concrete that would otherwise be treated as industrial waste. In the pavilion’s paving and structural elements—including floor slabs and benches—about 81 m³ of CP Concrete was employed, capturing and storing roughly 3 tons of CO2 across all stages of its production.

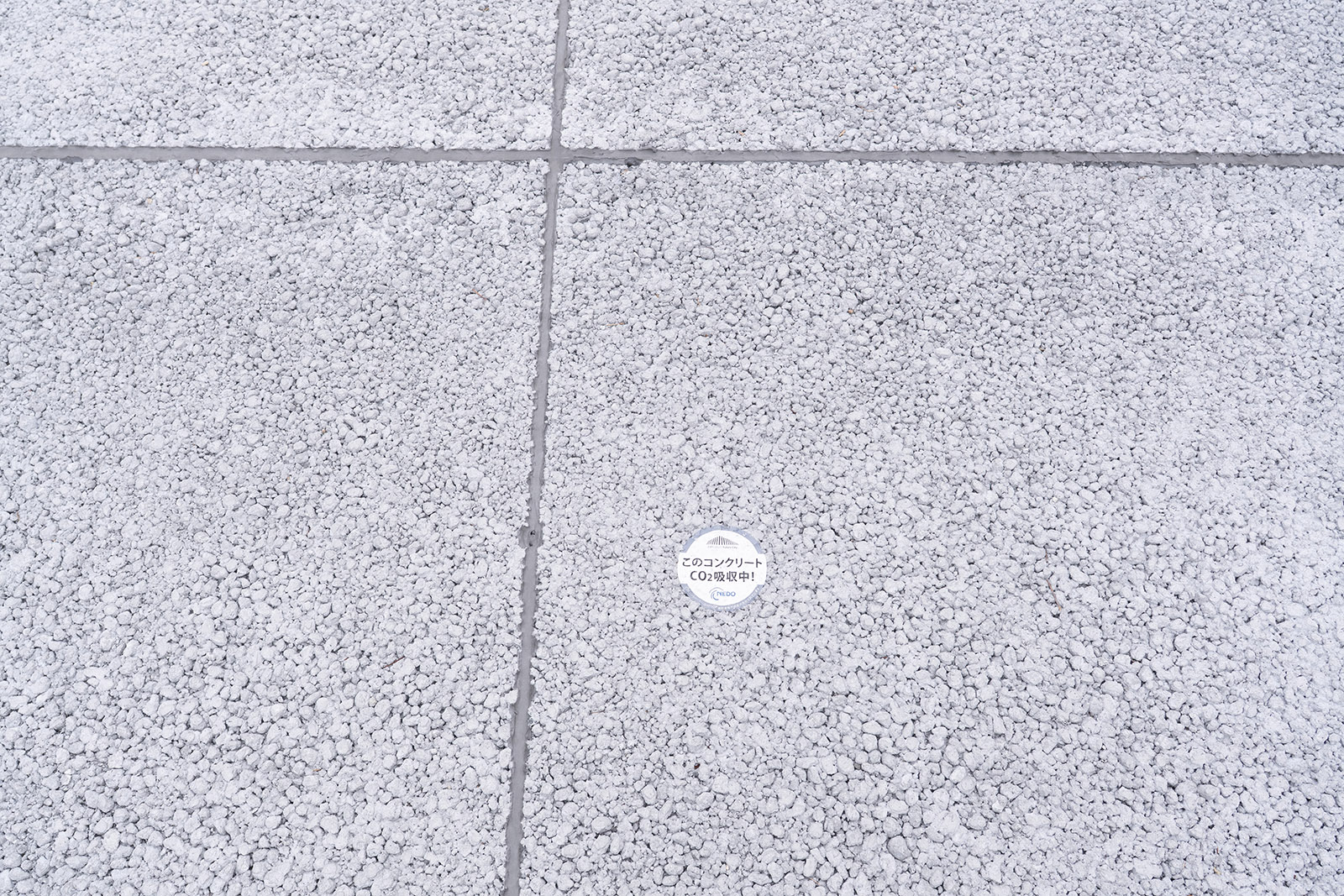

Paving near the entrance of the Future City Pavilion

Paving near the entrance of the Future City PavilionTwo types of benches have been installed near the entrance and inside the pavilion. One type incorporates CO2 absorption and fixation in two stages: first during the production of the concrete materials, and then again when those CO2-fixed materials are used to produce the concrete for the benches. The other type involves CO2 absorption and fixation only during the material production stage. Both types of CP Concrete benches continue to absorb CO2 from the atmosphere even while on display, each bearing a sticker that reads ”Currently Absorbing CO2!” After the Expo concludes, the final amount of CO2 absorbed and fixed will be measured.

CP Concrete bench with “Currently Absorbing CO2!” sticker

CP Concrete bench with “Currently Absorbing CO2!” stickerPorous CP Concrete is used to pave the main entrance area of the pavilion. It is also used in the paving at the pavilion’s exit and along the seaside service passageway.

CP Concrete is being refined through various demonstration projects to enhance its core technologies and to test different production methods and material combinations. These efforts aim to chart pathways for its social implementation, contributing to the realization of a decarbonized society.

Porous CP Concrete paving

Porous CP Concrete pavingOver 80% Reduction in CO2 Emissions

At the Expo Messe WASSE in the West Gate Zone, environmentally conscious concrete was also used. Although not visible—since it was employed as precast concrete for the building’s foundation—WASSE is essentially supported by this material. Four types of architectural precast components were produced using this technology, delivering over an 80% reduction in CO2 emissions during manufacturing. After the Expo, these components will be dismantled and reused as Carbon Capture and Utilization (CCU) materials.

Precast concrete used in the foundation of Expo Messe WASSE (Photo courtesy of Takenaka Corporation)

Precast concrete used in the foundation of Expo Messe WASSE (Photo courtesy of Takenaka Corporation)During ground improvement work for the construction of the Mitsubishi Pavilion, CCU materials were also applied, capturing and fixing about 160 kilograms of CO2. This approach achieved a reduction of roughly 5% in CO2 emissions compared with conventional ground improvement methods. The reinforced ground will undergo quality inspections even after the Expo concludes.

Ground improvement work (Photo courtesy of Takenaka Corporation)

Ground improvement work (Photo courtesy of Takenaka Corporation)420 kg of CO2 Fixed per Ton of Artificial Limestone

At the Sumitomo Pavilion in the East Gate Zone, eco-friendly concrete can also be seen. The pavilion’s exterior blocks contain artificial limestone produced with CO2 as a blending material.

The artificial limestone used here was produced from calcium-containing waste materials—such as gypsum board—combined with CO2. Each ton of artificial limestone fixes about 420 kilograms of CO2, one of the highest levels in the world. Throughout the pavilion, roughly 500 kilograms of CO2 recycling artificial limestone were used, fixing approximately 210 kilograms of CO2.

Exterior blocks of the Sumitomo Pavilion

Exterior blocks of the Sumitomo PavilionThe applications of CO2 recycling artificial limestone extend beyond concrete. Development is also underway for paper and resin products that incorporate this material, as well as next-generation reef structures to help restore seaweed habitats. In June 2025, a pilot-scale facility with about ten times the production capacity of existing equipment began operation, paving the way for the practical use of artificial limestone.

Applications of CO2 recycling artificial limestone

Applications of CO2 recycling artificial limestoneLeft: Paper and other products Right: Reefs for seaweed habitat restoration

■ Toward Carbon-Neutral Mobility

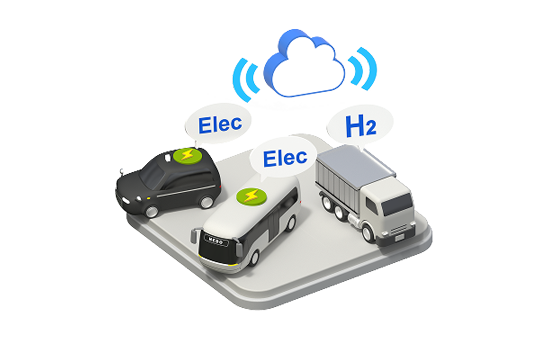

Mobility is fundamental to human activity, and even in 2050, automobiles will remain a primary means of transportation. While the number of electric vehicles (EVs) is rising, fossil-fuel vehicles such as those powered by gasoline and diesel still dominate. EVs also face challenges, such as long charging times, which limit their convenience as a seamless mode of transport. At the Expo, initiatives supported by the GI Fund are being showcased, ranging from the development of alternative fuels to efforts to reduce EV charging times.

Ten Daily Shuttle Buses Running on Synthetic Fuel

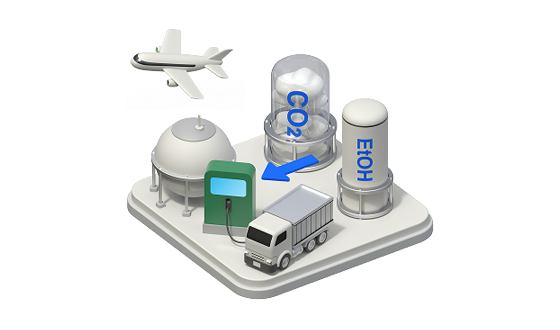

Shuttle buses operate between the Umekita Green Place Bus Terminal near Osaka Umeda Station and the Expo 2025 Osaka, Kansai venue. Of the 19 daily services, ten are now operating on synthetic fuel, replacing fossil fuels.

Shuttle bus running on synthetic fuel (Photo courtesy of ENEOS)

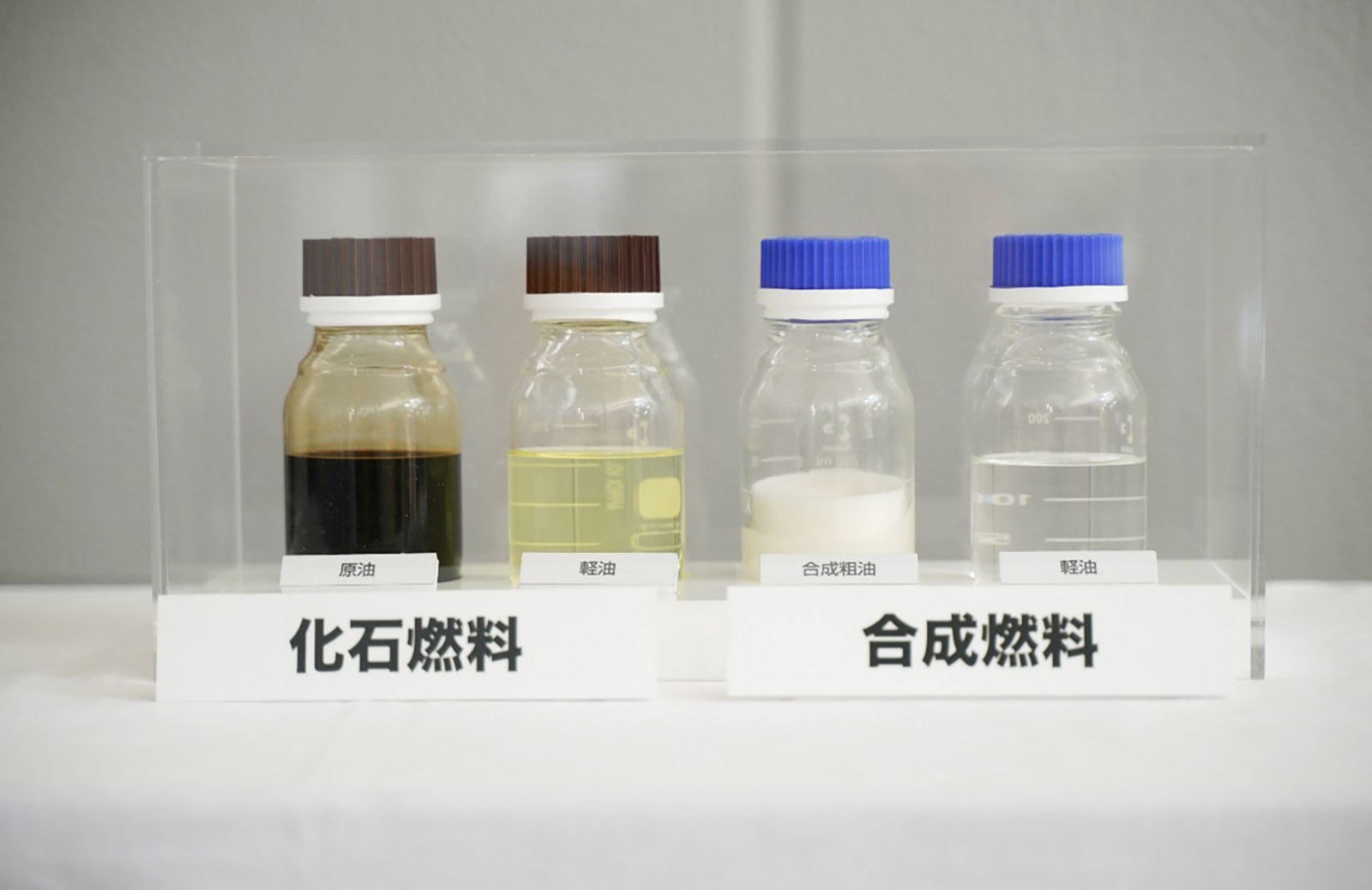

Shuttle bus running on synthetic fuel (Photo courtesy of ENEOS)This is Japan’s first use of synthetic fuel, made entirely from hydrogen and CO2, to power commercial vehicles. The fuel is manufactured from hydrogen derived from renewable energy and captured CO2. As a carbon-neutral fuel, it reduces CO2 emissions across its entire life cycle, from production through use. Another major advantage is that vehicles require no special modifications to run on it—conventional fuel can simply be replaced with synthetic fuel. Naturally, ride quality and performance remain unchanged, allowing for a carbon-neutral experience without compromising comfort.

Left: Fossil crude oil and diesel oil Right: Synthetic crude oil and diesel oil.

Left: Fossil crude oil and diesel oil Right: Synthetic crude oil and diesel oil.Wireless Charging for EV Buses

Visitors to the Expo can experience future modes of mobility firsthand. One example is the “eMover,” an EV bus that helps transport people around the Expo site. About 30 eMovers are in operation, six of which are equipped for wireless charging—recieving power from coils embedded in the roadway while either stopped or in motion. Although wireless charging cannot supply all the electricity required for operation, it is regarded as an important technology for reducing charging times at depots.

Wireless charging–enabled EV bus “eMover”

Wireless charging–enabled EV bus “eMover”At the Expo, wireless charging is being demonstrated by transmitting power between coils embedded in the roadway and receiving coils mounted beneath the eMover buses. Charging while stopped is available at the East Gate North stop, while dynamic wireless charging is being tested along a section of the Expo site’s outer loop on the west side of the Future Life Zone. In the latter case, ten sets of transmission coils are embedded across a 50-meter stretch of road to enable wireless charging while driving. The coils are housed in white rectangular precast concrete units placed on the roadway, allowing the buses to recharge as they pass over them.

Left: Precast coils embedded in the roadway Right: Illustration raising awareness of wireless charging

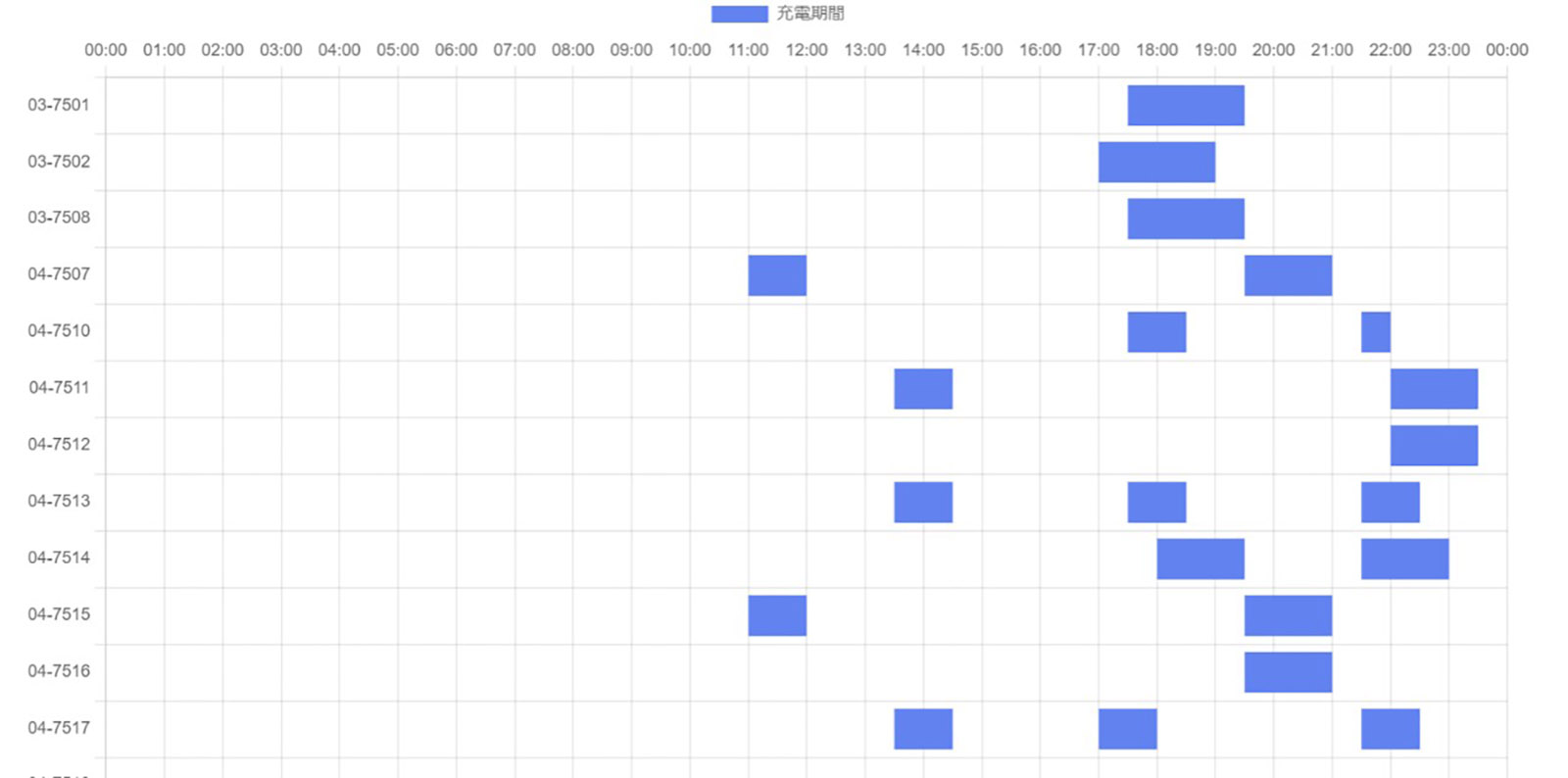

Left: Precast coils embedded in the roadway Right: Illustration raising awareness of wireless chargingAt the Expo, a comprehensive energy management system is being demonstrated for the entire fleet of about 30 eMover buses, including six equipped for wireless charging. The system not only manages charging but also plans charging cycles based on vehicle operating schedules. By integrating energy management with fleet operations, the system aims to curb potential spikes in peak electricity demand and achieve more balanced power consumption as EV buses become more widespread in the future. After the Expo, durability tests of the embedded transmission units, evaluations of usability and construction challenges, and further refinements of the energy management system will be conducted, with the goal of on-road pilot projects in 2028.

Energy management system screens for the “eMover” EV bus. The top image shows vehicle location and charging status. (Images courtesy of Kansai Electric Power Company)

Energy management system screens for the “eMover” EV bus. The top image shows vehicle location and charging status. (Images courtesy of Kansai Electric Power Company)

Organizations and projects featured in Part 1 of the GI Fund showcase:

- Sustainability Dome and Expo Arena “Matsuri” (Concrete): CUCO Consortium / Kajima Corporation, GI Fund project “Development of Concrete and Related Technologies Using CO2”

- “Future City” Pavilion (Concrete): CP Concrete Consortium

- Expo Arena “Matsuri” (Precast concrete) and Mitsubishi Pavilion (Ground improvement): CUCO Consortium / Takenaka Corporation, GI Fund project “Development of Concrete and Related Technologies Using CO2”

- Sumitomo Pavilion (Artificial limestone): Sumitomo Osaka Cement, GI Fund project “Development of Concrete and Related Technologies Using CO2”

- Shuttle buses: ENEOS, GI Fund project “Development of Fuel Production Technologies Using CO2 and Related Materials”

- EV bus “eMover”: Kansai Electric Power Company, Daihen, Osaka Metro, Obayashi Corporation, East Nippon Expressway Company, GI Fund project “Smart Mobility Society Development”

Related Articles