*This article is a translation of a Japanese article originally published on September 12, 2025.

The second installment of this series on the achievements of NEDO’s Green Innovation Fund (GI Fund), showcased at Expo 2025 Osaka, Kansai, highlights the carbon-neutral manufacturing to come, with a central theme of utilizing CO2.

■ Toward Carbon-Neutral Manufacturing

In Part 1, we looked at demonstration projects that reduce CO2 emissions. Equally important, however, are the technologies now being developed to capture and repurpose CO2. Carbon dioxide can be transformed into feedstock for fuels, tableware, clothing, and more. By using both newly generated and already released CO2 as raw material, we can prevent further increases in atmospheric concentrations. These factories of the future transform CO2 into valuable resources.

Capturing CO2 for Dry Ice and City Gas Feedstock

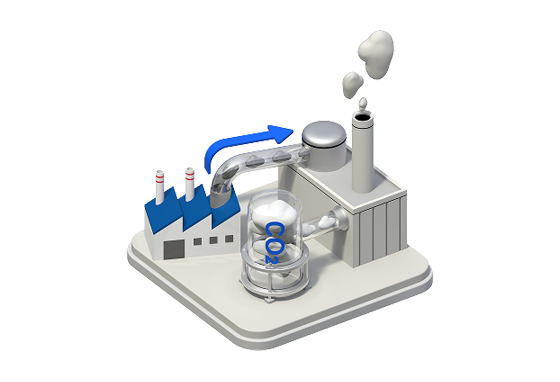

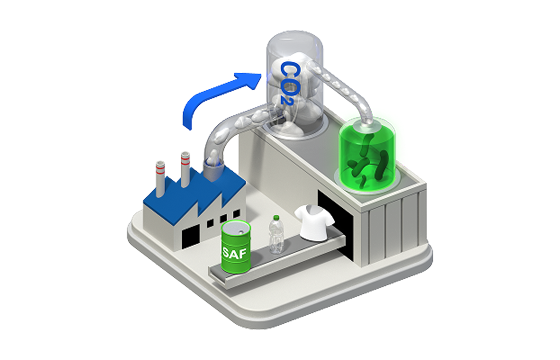

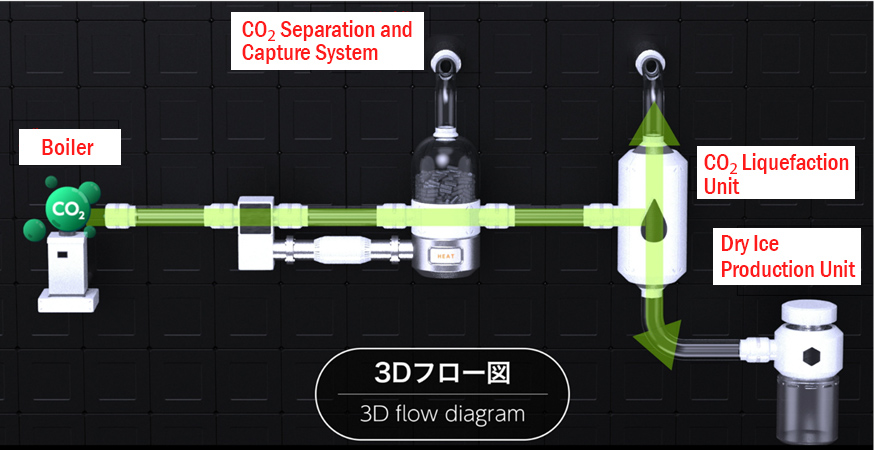

The Carbon Recycle Factory, located southeast of the East Gate Zone, captures and recycles CO2. At its Nature’s Blessings Station, CO2 is captured from boiler flue gas and converted into feedstock for dry ice and methane (a city gas component). Visitors can see the full cycle—from capture to utilization—all in a single integrated process.

CO2 separation and capture system at the Nature’s Blessings Station

CO2 separation and capture system at the Nature’s Blessings StationThe CO2 separation and capture system installed here can capture up to 300 kilograms of CO2 per day. It employs a new Na-Fe oxide–based solid sorbent packed inside tanks.

Left: Sodium ferrite Right: Na-Fe oxide solid sorbent (black pellets), used in CO2 separation and capture systems

Left: Sodium ferrite Right: Na-Fe oxide solid sorbent (black pellets), used in CO2 separation and capture systemsThe sorbent absorbs CO2 at room temperature and releases it when heated to 100°C. This property is utilized for CO2 separation and capture, with waste heat from the boiler used for the heating process. The captured CO2 is then liquefied and purified, and used in two ways: to produce dry ice for cooling within the Expo grounds, and to supply a methanation facility in the Carbon Recycling Factory, where CO2 reacts with hydrogen to synthesize methane.

CO2 capture flow: CO2 is captured from boiler flue gas on the left, processed by the separation and capture system in the center, liquefied, and then supplied to the dry ice production unit at the lower right and to a methanation unit. (Photo courtesy of Air Water)

CO2 capture flow: CO2 is captured from boiler flue gas on the left, processed by the separation and capture system in the center, liquefied, and then supplied to the dry ice production unit at the lower right and to a methanation unit. (Photo courtesy of Air Water)The system installed at Nature’s Blessings Station is compact enough to be installed even in limited spaces, making it suitable for capturing CO2 from combustion flue gases at facilities ranging from small workshops to large industrial plants.

Turning CO2 into Resources with Microalgae

At the Japan Pavilion, visitors can explore bio-manufacturing initiatives that transform CO2 into valuable resources using microorganisms—specifically microalgae and hydrogen-oxidizing bacteria.

One case features microalgae cultivation. Visitors at the pavilion can see two species being cultivated: Botryococcus and Spirulina.

Botryococcus is notable for its high lipid content—about half its body weight—and yields oil at a rate 14 times higher than corn, making it highly suitable for biofuel production. In rounded cultivation tanks, Botryococcus cultures are supplied with CO2 and illuminated for photosynthesis. Looking closely into the tanks reveals particles floating in the liquid—these are the growing algae. The process begins in the pavilion’s backyard, where the algae are first cultivated; once they reach a certain size, they are transferred to the exhibition-area tanks for further growth before being harvested.

Cultivation tank for Botryococcus

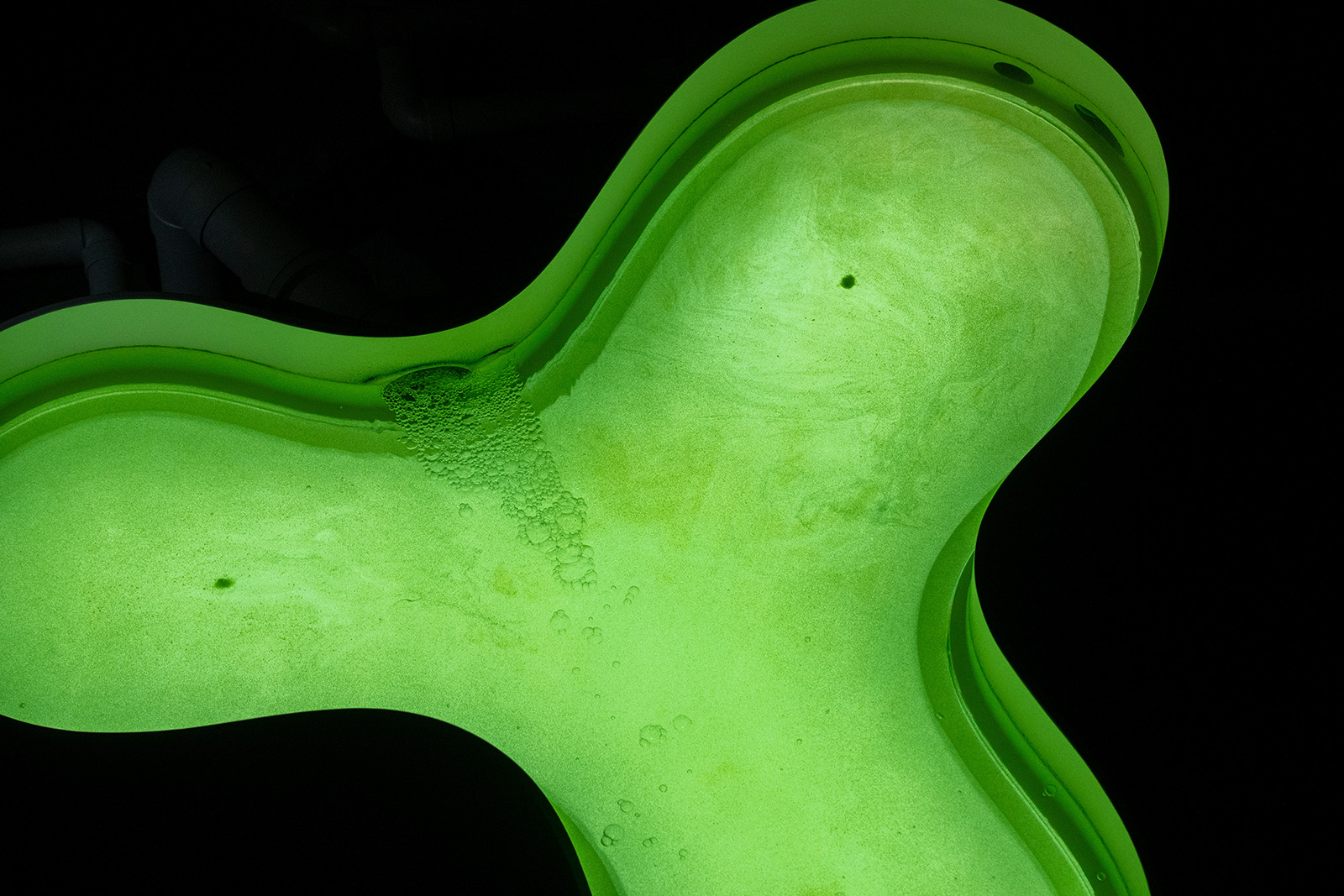

Cultivation tank for BotryococcusSpirulina, on the other hand, is a nutrient-rich “superfood.” At the Japan Pavilion, it is cultivated in transparent tubes through which a CO2-infused liquid medium flows. The liquid circulating in the tubes returns to a tank in the backyard, where it is illuminated for photosynthesis, before being pumped back into the tubes inside the pavilion. This continuous circulation supports its cultivation.

Spirulina flowing through transparent tubes at the Japan Pavilion

Spirulina flowing through transparent tubes at the Japan PavilionInside the pavilion, the Algae Curtain creates a forest-like landscape with transparent tubes through which Spirulina flows. The green Spirulina helps evoke the feel of a living forest. Looking closely, one can see green liquid moving through the tubes—Spirulina under cultivation.

A close-up view of Spirulina circulating inside transparent tubes (Photo courtesy of the Ministry of Economy, Trade and Industry)

A close-up view of Spirulina circulating inside transparent tubes (Photo courtesy of the Ministry of Economy, Trade and Industry)Besides the two cultivated at the pavilion, many more species of microalgae hold potential for applications in manufacturing. Depending on their properties, microalgae can be used as raw materials for clothing, PET resin, jet fuel, among other products.

At the Japan Pavilion, panels introduce the features of 32 algae species, with Hello Kitty dressed in algae-inspired costumes to highlight their appeal. Modeled on real forms—spiral, floral, angular, and more—the designs offer visitors a friendly and engaging way to learn about algae.

Hello Kitty in algae-inspired costumes introducing the appeal of algae

Hello Kitty in algae-inspired costumes introducing the appeal of algaeThe two species of microalgae under cultivation at the pavilion are later used as raw materials, demonstrating how living algae can be effectively utilized in manufacturing.

Algae applications made possible through GI Fund outcomes, showcased as part of the MATSURI initiative (Photo courtesy of the Ministry of Economy, Trade and Industry)

Algae applications made possible through GI Fund outcomes, showcased as part of the MATSURI initiative (Photo courtesy of the Ministry of Economy, Trade and Industry)Another microbial initiative showcased at the Japan Pavilion is the use of hydrogen-oxidizing bacteria. Visitors can see a vessel partially made with biodegradable biopolymers derived from CO2 as a carbon source. These bacteria can produce biopolymers from CO2 that serve as the basis for plastic and textile products. A major advantage of these biopolymers is that, while matching the quality of conventional petroleum-based products, they are also readily biodegradable in seawater. By harnessing the power of diverse microorganisms to develop renewable raw materials and biodegradable products, these technologies contribute to building a circular society.

The vessel partially made with CO2-derived biodegradable biopolymers using hydrogen-oxidizing bacteria

The vessel partially made with CO2-derived biodegradable biopolymers using hydrogen-oxidizing bacteria

Organizations and projects featured in Part 2 of the GI Fund showcase:

- CO2 separation and capture system at Nature’s Blessings Station: Air Water, TODA Kogyo, Saitama University, GI Fund project “Development of CO2 Separation and Capture Technologies”

- Microalgae at the Japan Pavilion: Chitose Laboratory, GI Fund project “Advancing Carbon Recycling with CO2-Based Bio-Manufacturing Technologies”

- Biodegradable polymers at the Japan Pavilion: Kaneka, GI Fund project “Advancing Carbon Recycling with CO2-Based Bio-Manufacturing Technologies”

Related Articles