Budget and 2050 Target Outcomes

- Budget

Up to449.9B¥

- CO2Reduction Effect

Approx.1.3Bt/yr

- Economic Effect

Approx.40T¥/yr

Related Contents

There are no related contents.

Project Implementing Entities

[Research and Development 1]

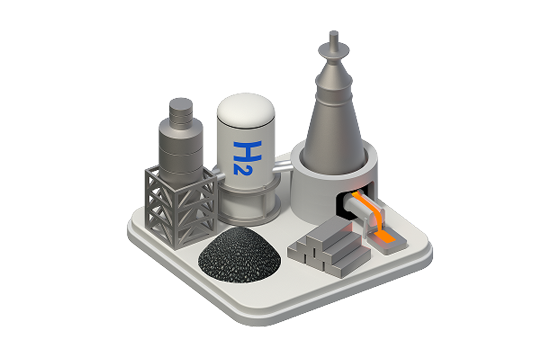

Development of hydrogen reduction technology using blast furnaces

| Theme | Entity |

|---|---|

Development of hydrogen reduction technology utilizing on-site hydrogen | ManagerNippon Steel Corporation |

| JFE Steel Corporation | |

| Kobe Steel, Ltd. | |

| The Japan Research and Development Center for Metals | |

Development of low-carbon technologies using external hydrogen and CO2 contained in blast furnace exhaust gas. | ManagerNippon Steel Corporation |

| JFE Steel Corporation | |

| Kobe Steel, Ltd. | |

| The Japan Research and Development Center for Metals |

[Research and Development 2]

Development of direct hydrogen reduction technology that reduces iron ore with hydrogen only

| Theme | Entity |

|---|---|

Development of direct hydrogen reduction technology | ManagerNippon Steel Corporation |

| JFE Steel Corporation | |

| The Japan Research and Development Center for Metals | |

Development of technology to remove impurities in electric arc furnaces using directly reduced iron | ManagerNippon Steel Corporation |

| JFE Steel Corporation | |

| Kobe Steel, Ltd. | |

| The Japan Research and Development Center for Metals | |

Development of high-efficiency melting technologies by an electric smelting furnace using directly reduced iron | ManagerNippon Steel Corporation |

| The Japan Research and Development Center for Metals |